Understanding the complexities of single skin metal: Fabrication

By Metal Construction Association.

When using single skin metal for the exterior of buildings, it is crucial to understand the fabrication process to ensure the best performance.

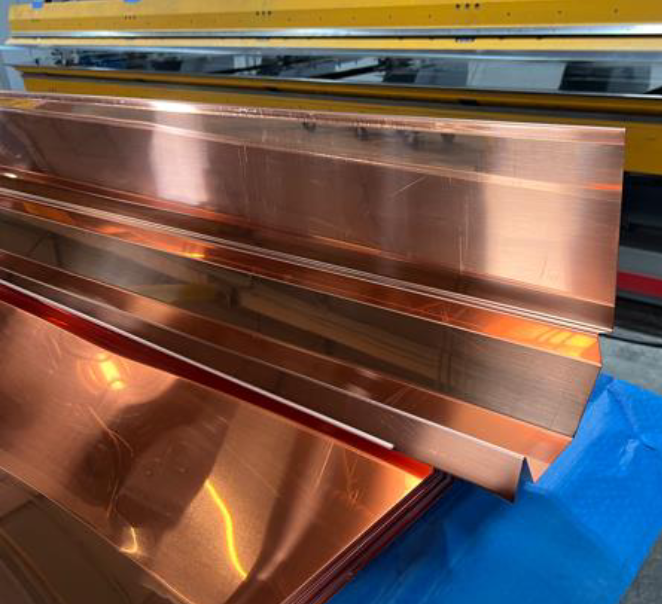

Single skin metal, also known as single-skin metal cladding or single skin metal plates, is often chosen for industrial and commercial projects because of its aesthetic and functionality. But, for this material to perform as best as possible, the fabrication process is a crucial consideration. This is the process that takes the single skin metal from its “as manufactured” state into the end product used by contractors.

This begins even before the metal is fabricated, starting with the selection of what type of metal to use. Different metals change what width and length the panels can ultimately be. Some metals come in sheet stock material which maintains a fixed width and length. Generally, this category includes thicker plate products and a few natural metals. Other metals can come in coil format which has a limited width, but the fabricator can adjust the length of the finished product. Natural metals, pre-painted and anodized aluminum, metallic coated steels and basic steels are often only available in coil format.

It is important when choosing your metal type to consider how thick the different materials are. Metal thickness affects the bending strength of the fabricated panels. It also can change the aesthetic appearance of the final panels as “oil canning” can occur at certain thicknesses. This is when surface waviness appears due to significant changes in metal temperature. Generally, rolled products tend to include 22 to 24 gauge for steel and 0.032” to 0.050” for aluminum sheets. For the more natural metals, such as zinc and copper, there are a variety of thicknesses. Aluminum plates will often be in the 0.063” to 0.190” range.

Beyond dictating bending strength, the thickness of the material changes the fabrication process and when the metal is finished. Thinner materials are often painted prior to fabrication while heavier materials, beyond the 0.080 aluminum will often be painted or anodized after fabrication.

Learn more about Metal Construction Association (MCA) in their Coffee Shop Directory or visit www.metalconstruction.org.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In