THALMANN Maschinenbau AG: The Swiss Precision of Folding Machines

By CIDAN Machinery Group.

As THALMANN Maschinenbau AG showcases, Swiss precision is not limited to watches.

Around the world, the reputation of a Swiss watch is one of exquisite craftsmanship, accuracy, dependability, and sturdiness. THALMANN Maschinenbau AG, a Swiss-based company in Frauenfeld, also embodies these quintessential Swiss values through their cutting-edge long folding machines. THALMANN has been producing single and double-folding machines since 1960. These folding machines facilitate the economical production of sheet metal profiles for industrial and trade sheet metal processing companies, making them a top player in the folding technology market. THALMANN machines boast remarkable precision, flexibility and innovative automation solutions, cementing their position as a leading name in the industry.

“We don’t build watches, but we do build high-precision folding machines in which, as with a Swiss watch movement, the multitude of different individual components are optimally matched to each other and match each other smoothly.” Gerhard Zech, managing director at THALMANN and FORSTNER.

Otto, the trailblazer

Today’s THALMANN Maschinenbau AG, which has been part of the Swedish CIDAN Machinery Group since the beginning of 2022, can be traced back to the one-person business for metalworking and metal construction founded by Otto Thalmann in 1948. Almost 75 years later, around 50 people are employed at the Frauenfeld site (Canton Thurgau). In addition to CIDAN Machinery from Sweden, THALMANN and the Austrian-based companies FORSTNER (coil handling systems) and nuIT (software solutions) belongs to the globally active group, with a total of about 300 employees. And the trend is rising.

High innovative strength

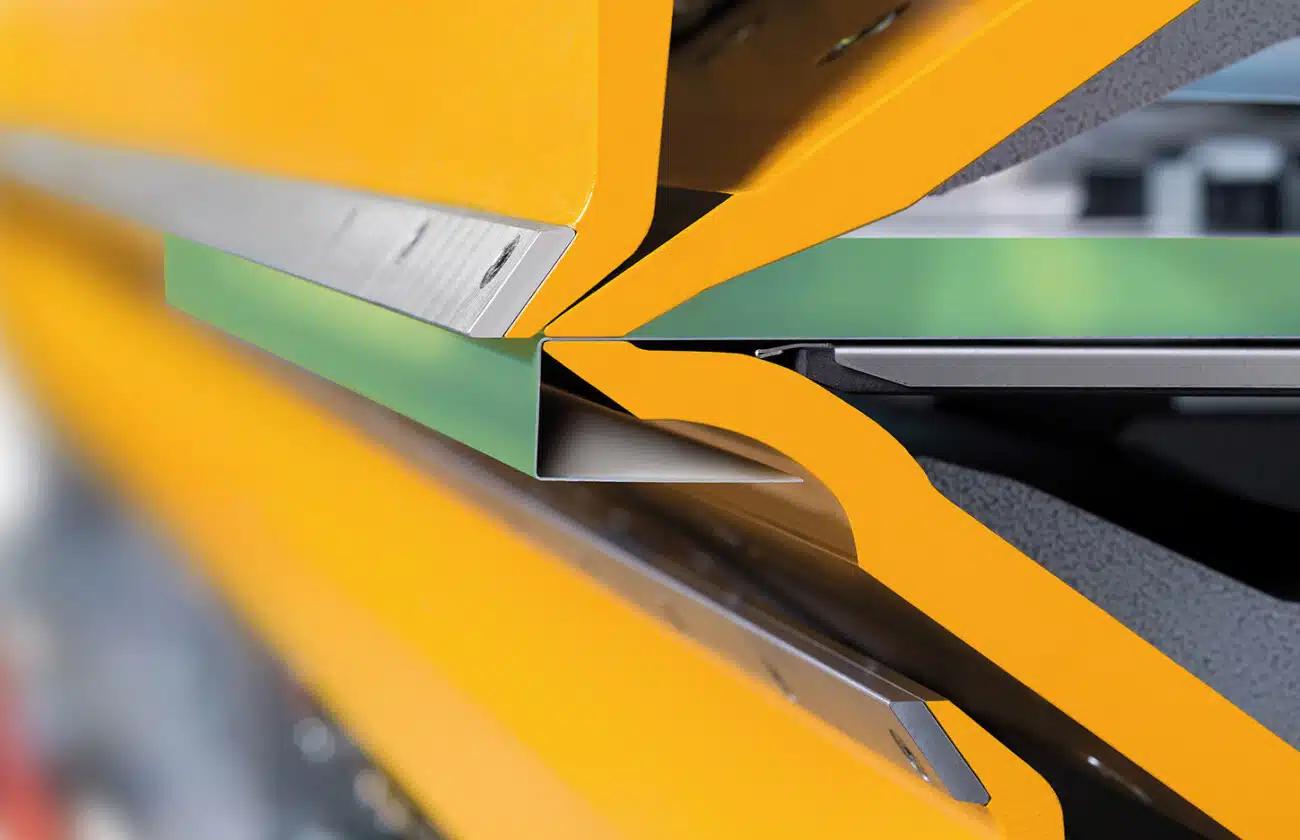

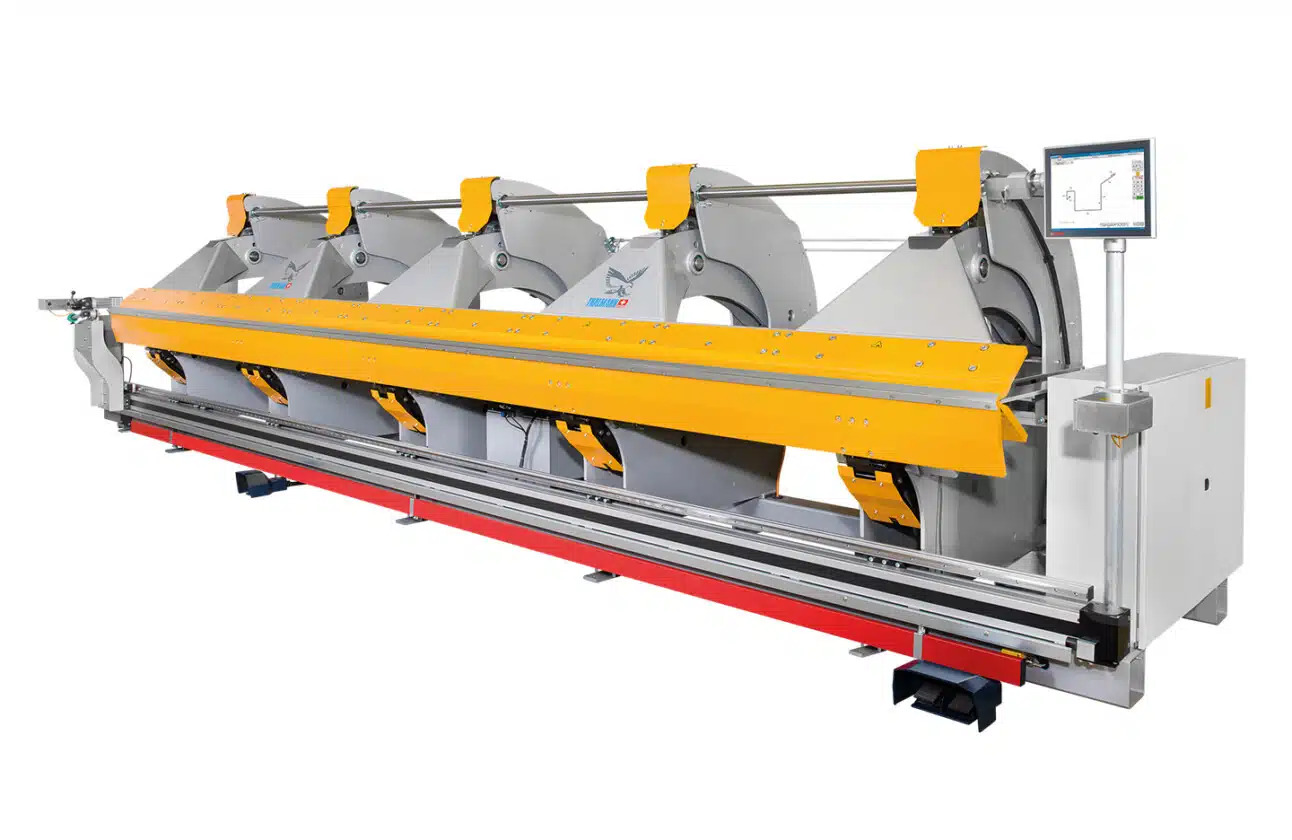

THALMANN stands for developing innovative solutions that help sheet metal processing companies to operate profitably and secure a solid competitive position, and it is one of the central driving forces. Optimized folding clearance and high flexibility enable various tool shapes. The unique kinetic control shaft technology ensures unrestricted work performance and synchronous power distribution over the entire machine length for unrestricted work performance. Even higher folding precision can be achieved with the dynamic crowning function. The exclusive vertical design principle (VFD) guarantees optimum clamping force transmission, and even faster, smoother bending processes are achieved with dynamic folding technology (DFT) and without any loss of folding precision. Lastly, the intensive development of modularly integrable automation solutions has contributed significantly to THALMANN’s success story.

Modular automation solutions

Time and cost pressure, staff shortages, digitization, and compliance with Industry 4.0 standards are some of the significant challenges of our time, which companies must face courageously, decisively, and, above all, with solutions. This is exactly what THALMANN has done with modularly integrable automation solutions: The complex manufacturing process is decisively simplified, and production efficiency has increased sustainably. Valuable time and high costs can therefore be saved. Personnel costs can especially be saved since the entire system can be operated by just one operator.

For this purpose, THALMANN offers three independent automation units: the automatic sheet feed-in device, the automatic sheet flipping device, and the automatic part unloader with buffer/garage. The customers themselves can determine the degree of automation. Solutions are offered that can be adapted to individual needs and retrofitted to newer generation machines.

Single and double folders

THALMANN covers the needs of customers from trade and industry with three core models:

The TZ SINGLE FOLDER models are ideally suited for basic folding processes and therefore, for typical architectural, cladding and roofing companies.

The TD DOUBLE FOLDER models are the first choice for larger architectural, cladding, and roofing companies as well as for industrial production where high-performance criteria must be met.

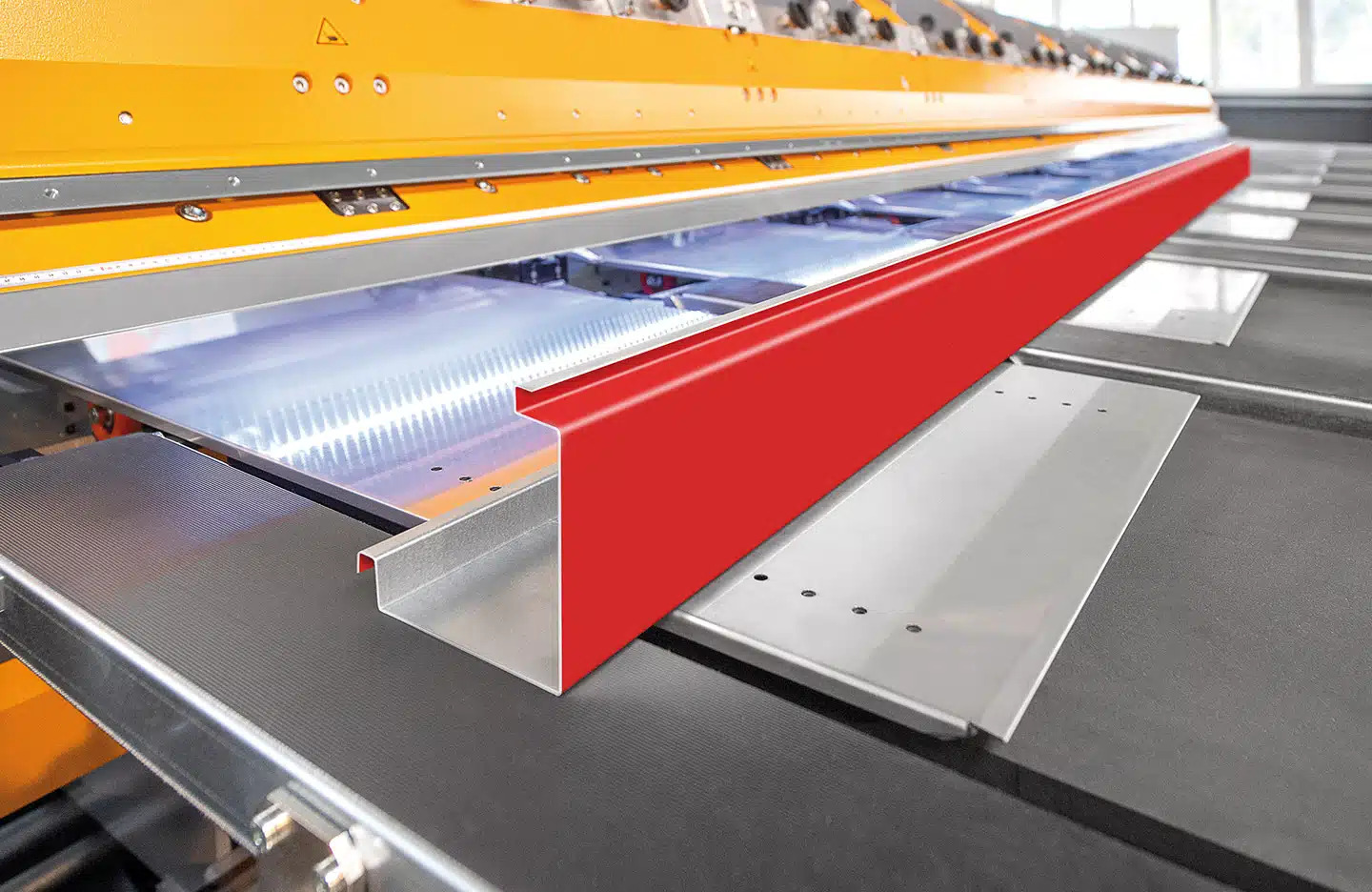

The TC DOUBLE FOLDER models convince sheet metal processing companies with the precise high-performance folding of sheets up to 3 mm thick at high processing speeds.

All information about the model variants can be found at www.thalmann-ag.ch

Unique customer benefits

The integration of THALMANN Maschinenbau AG into the CIDAN Machinery Group brings a unique customer benefit: a comprehensive range of machines, tried-and-tested software solutions, and a wide range of services from a single source. In the spirit of a ONE-STOP-PARTNER, which accompanies customers holistically in their business development and offers future-oriented solutions for every company size and every need – from individual solutions and used machines for start-ups and smaller roofing companies, to individually coordinated machinery, to fully automated, highly efficiently producing large-scale plants for industrial production.

The headquarters of THALMANN Maschinenbau AG is located in Frauenfeld (Switzerland) in the canton of Thurgau, just under 30 minutes by car from Zurich Airport.

The innovative single and double-folding models are manufactured in the production and assembly halls and put through their paces before delivery.

THALMANN attaches great importance to highly trained, motivated, and cheerful employees. They are the backbone of the company and a key success factor.

The first long folding machine from THALMANN (type Standard 60) was delivered on 25 August 1960. It had a working length of 6.2 m and 1.0 mm sheet iron folding capacity.

The TD double folder from THALMANN folds sheet metal profiles automatically, quickly and precisely in both directions. The curved clamping cheek tool provides additional folding freedom.

The unique kinetic control shaft technology ensures unrestricted work performance and synchronous power distribution over the entire length of the machine.

The exclusive, vertical design principle (VFD) of the TZ single folder develops enormous clamping forces directly at the clamping point.

With the TD double folder, exclusive dynamic folding technology (DFT) guarantees even faster and smoother bending processes without losing folding precision.

The TC double folder was developed especially for the precise, high-performance folding of sheet metal profiles with thick material thicknesses. Even 3 mm thick sheet steel is no problem for the power pack.

The modularly integrable automation solutions simplify the complex manufacturing process, increase production efficiency and significantly reduce personnel costs, as just one employee can operate the entire system.

Significantly reduced working times directly at the machine and high efficiency gains can be achieved with the automatic lateral sheet metal insertion unit.

The automatic sheet metal turning unit ensures a high reduction in sheet metal part handling and smoother, more consistent folding processes.

After folding, the finished folded sheet metal profiles are automatically picked up by the machine and conveyed to the edged parts buffer for easy removal.

The complete sheet metal removal unit can be automatically stowed under the edged parts buffer. This means that orders can be processed again – even without full automation.

Original article source: CIDAN Machinery Group

Learn more about CIDAN Machinery Group in their Coffee Shop Directory or visit www.cidanmachinery.com.

About CIDAN Machinery Group

CIDAN Machinery is a company group within the sheet metal industry. CIDAN-machines are made in the CIDAN Machinery factory in Götene, Sweden with 115 years of experience in the field. Machines for professional processing of coils are made in Austria by CIDAN Machinery Austria GmbH, formerly known as Forstner GmbH, with over 60 years of experience in the field. We also have a factory in Switzerland that has manufactured the Thalmann long-folder machine for over 70 years.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In