New Packaging System Improves Workflow and Reduces Errors on the Jobsite

By Colin Sheehan, RCS Reporter.

Learn the benefits of Tremco's new packaging system and how it can benefit your company.

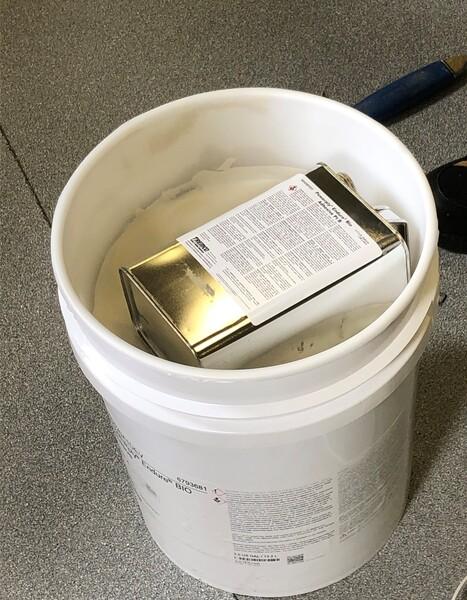

David Pinckney, a Tremco WTI Field Resources Supervisor was working with RoofTech to install POWERply Endure BIO Adhesive TF. Recently, POWERply had gone through a packaging change and this project was one of the first where Tremco shipped the product with the new and improved packaging system.

The new packaging places the curative inside the pail with the rest of the adhesive. Initially, David thought the curative was lost in transit, but soon found it securely in the pail and quickly realized the benefits of this packaging system for his WTI team and contractors.

“[This new set packaging] is a good move for Tremco and will help make each project go smoother with less hassles,” said David. He also highlighted several on-the-job benefits that the new packaging system provides, including:

-

Reduced pre-job stress of assuring all needed materials are on site.

-

It’s impossible to miss mixing the curative into the base because it is right on top.

-

A less cluttered mixing area on the roof which reduces mixing spills or errors on the roof.

-

The plastic pail is easier to open than the steel pail.

Additional benefits of the new packaging include:

-

An added screw cap on the curative eliminates accidental spillage when opening the lid.

-

The plastic 5-gallon pail is easier to crush and dispose of than the steel pails.

-

There are no steel rust rings on the roof with the new plastic pails.

For contractors who need to perform high-quality work on an efficient time schedule, the new packaging system is a great improvement. It simplifies both the handling and mixing of POWERply Endure BIO Adhesive TF and makes clean-up quicker as contractors can simply dispose of the empty containers after the job is done.

Project specs:

Location: Bowling Green, KY

Completion date: June/August 2020

Client: Western Kentucky University - Potter Hall

Tremco products: POWERply Endure BIO Adhesive

Contractor: RoofTech

Tremco representative: Mike Chadwick

Project type: Repairs and Restoration

Learn more about Tremco WTI in their RoofersCoffeeShop® Directory or visit www.tremcoroofing.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In