Combating Corrosion & Waterproofing Problems

By ICP Building Solutions Group.

This project used an ASTEC RePly Roofing fluid-applied system to solve this unique situation.

When East Group Properties, a publicly traded real estate investment trust, decided that they needed to address the metal roof of their Riverbend One building, they turned to their property management group, Latter & Blum, for guidance. Latter & Blum put them in touch with Marsiglia Construction who proposed an ASTEC RePly Roofing fluid-applied system as a retrofit solution to the waterproofing and corrosion problems they were experiencing at the time.

The Riverbend Business Park is a three-building, business distribution complex located a few hundred feet from the Mississippi River and a couple miles from the New Orleans International Airport in St. Rose, Louisiana, a suburb of New Orleans. Of the three buildings, Riverbend One is the largest, coming in at 367,320 square feet of warehouse and office space. According to Paula Guidry, Senior Commercial Property Manager at Latter& Blum, Riverbend One was originally built in 1981 as a warehouse for D.H. Holmes department stores, which at one time was the largest department store chain in the Southern United States.

Marsiglia Construction, who had worked with Latter & Blum on a nearby metal roof, had been pursuing work on Riverbend Two, another metal roof on the campus, but by the time East Group had a chance to discuss ASTEC as a solution, they had already started work on Riverbend Two. When it came time to address Riverbend One, though, East Group decided to go with the fluid-applied option.

“The pricing is different, less with the coating than having to do a total reroof or some sort of a built-up, so that was a consideration,” said Lindsey Walston, Senior Asset Manager for East Group. Besides the savings, “the warranty was something that we definitely liked about it. A lot of coatings don’t have the 10-year warranty and one that is extendable,” continued Walston. “And you get the benefits of it being reflective.”

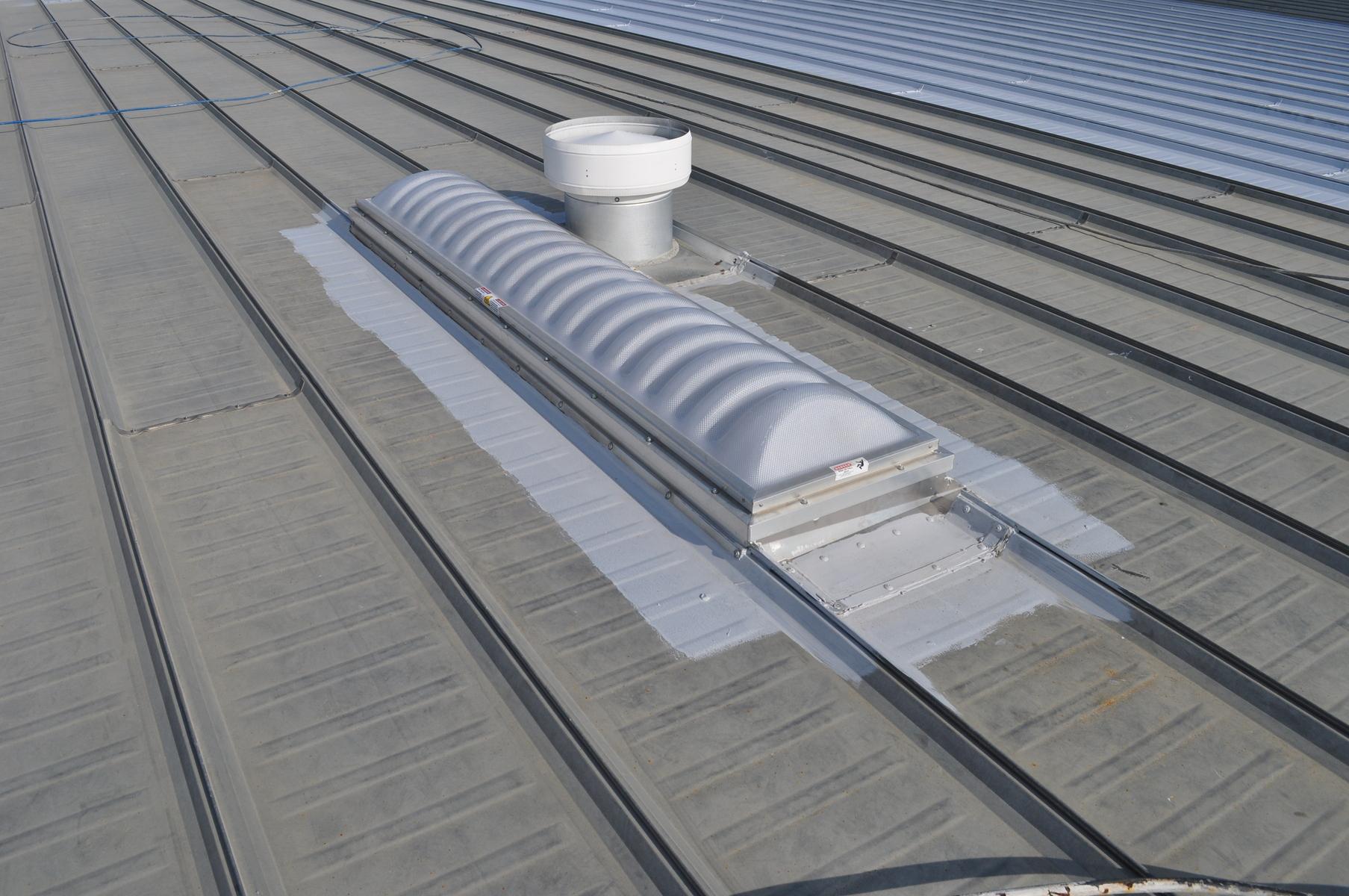

Riverbend One is a standard Butler pre-engineered metal structure, with Butler’s standing seam metal roof system. Of note, the roof was built with a minimal ½ in 12 slope. This mild pitch may have been a contributing or exacerbating factor for some of the issues that the roof was experiencing.

“As a general contractor who specializes in pre-engineered steel structures, when it comes to metal roofs we like to offer a minimum of 1 in 12 roof pitch,” explained Jason Litchfield, Project Manager for Marsiglia Construction. “Anything less than that you start getting water settling around fasteners and water at termination bars.”

Jason recalls that the corrosion caused by this settled water was so bad in some areas that he discovered holes as large as a foot or two in diameter during his initial walkthrough. The low pitch also caused some problems along the eaves of the building where indentations had formed during the installation of the roof. On a roof with more pitch, this would not have been much of a concern, but in instances with pitch this low, water has less opportunity to move off of the roof and will tend to settle in seemingly minor low areas.

All of these imperfections in the metal needed to be repaired before the ASTEC system could be applied. Marsiglia fabricated new metal to patch up the worst spots, including large sections along the eaves where they removed the existing fasteners and buffed down the existing metal to eliminate as many of the undulations as possible. They also removed existing patches when they felt they could improve the quality of the installation.

“Any of the patches that were sufficient enough were waterproofed over the top, but any that we needed to pull out, we pulled out,” said Litchfield. “We fabricated our flat stock to match the profile of the sheet, come up the high, and turn over the seam. That way our fasteners are on the high, not on the valley of the panel, so you’re less likely to have water intrusion because the water is not constantly hitting it like it is in the valley of the panel.”

Marsiglia Construction began work on Riverbend One in January. For the first four weeks on the job, they utilized sheet metal crews to complete repairs on the entirety of the 376,000 square feet. Once they were confident that the surface of the roof was sound, they began to prep the building but realized quickly that they would have their hands full keeping the roof clean enough to apply product. Between the building and the river, less than 500 hundred feet away, a storage yard for construction aggregate was blowing dust and sand over the roof surface all day long.

Marsiglia employed Mi-T-M rotary surface cleaners to attack the years of dirt, dust, sand and grime that had traveled from the aggregate yard to the roof surface. The rotary cleaners were more efficient than simple wand pressure washing systems that blast particles off the surface into the air and oftentimes back onto the roof. The rotary cleaners use a steam pressure wash system with rotating bristles that keep everything contained and traveling toward the gutters.

Even after this initial cleaning, Marsiglia constantly battled with that aggregate yard. Jason detailed the struggles. “That aggregate yard was a nightmare to deal with. We had to rinse that roof down every morning before we applied product. Then we had to use leaf blowers to try to dry it off…You had river sand, crushed concrete, limestone. It was a dust bowl. We had to clean that roof ten times more than we ever anticipated.”

Already delayed by the nonstop cleaning process, Marsiglia found themselves also working against Mother Nature. In February, a tornado in the area damaged the building, ripping a hundred feet of gutters and the associated downspouts right off the building. Day-to-day weather concerns caused further concerns as Litchfield recalled “a month where it rained every day…we had to watch the radar and the hourly forecast.” They had a crew on the roof with leaf blowers every morning ready to work, hoping that the weather would cooperate.

At the outset of the project, Marsiglia planned for an April completion date, but environmental factors caused the project to fall further behind schedule. All along, Litchfield communicated with Guidry and Walston to keep them in the loop. “Even though it took more time, they understood because of my communication with them. I tried to give them a weekly update with what was done and what we planned to do the following week.”

Marsiglia did eventually find enough dry days to apply the full ASTEC system, starting with ASTEC’s B-16-71 Metal Primer. The B-16-71 product both serves to improve adhesion for further coats and encapsulates existing rust and corrosion, preventing any further deterioration. Marsiglia spot primed areas with heavier rust and followed with a full pass on the entirety of the roof to ensure rust encapsulation.

At seams and penetrations, ASTEC’s specialty waterproofing products were used to ensure that the membrane would maintain its monolithic weatherproof properties. ASTEC WPM 9 and ASTEC Fibered WPM 10 provide additional durability to deal with the expansion and contraction of thermal shock, though the effects of thermal shock are further reduced by the reflective and emissive properties of the ASTEC 2000 Finish product, which was applied in two passes to complete the ASTEC RePly system.

As it was specified and completed on this project, the ASTEC system will be guaranteed leak free by a ten-year renewable warranty, backed by the manufacturer. At the end of the ten-year period, the building owner will have the option to add another ten years to their warranty after the roof is inspected and the protective finish product is reapplied, according to manufacturer’s spec.

In the end, all parties involved were extremely satisfied with this project. “Marsiglia Construction did a phenomenal job on this project,” said John Brock, Regional Director for ASTEC RePly Roofing. “From a manufacturer’s perspective, we knew going in that Marsiglia was the best contractor for this job. The way they handled the challenges confirmed our confidence in them."

Litchfield walked the finished roof with representatives from East Group and Latter & Blum who were “ecstatic.” He said, “they not only appreciated our work and our communication, they were extremely impressed with the ASTEC system itself; with the heat reflective properties and the water proofing agents…Now they are 100% leak-free.”

“It’s easy and it’s not as disruptive to your tenants. You’ve got a 367,000 square foot building and a number of tenants in there doing business at all hours of the day. They [roofing professionals] are up there, they’re pressuring washing and they’re coating. It’s much easier,” Walston explained. “This was our first experience with a coating system. I think it’s turned out great, I was up on the roof a month ago and it looks fantastic.”

Learn more about ICP Building Solutions Group in their RoofersCoffeeShop® Directory.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In