Get More From Your Metal Folders

By Cass Jacoby, RCS Reporter.

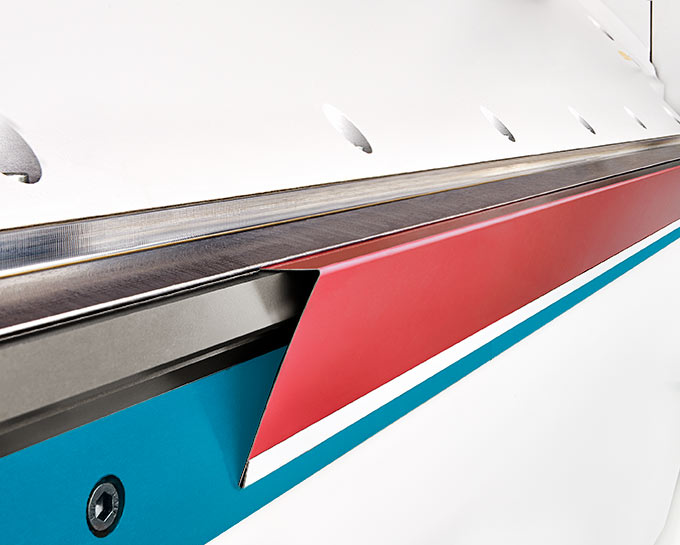

The innovative F-Geometry of MAX-F has companies wanting to upgrade their folders.

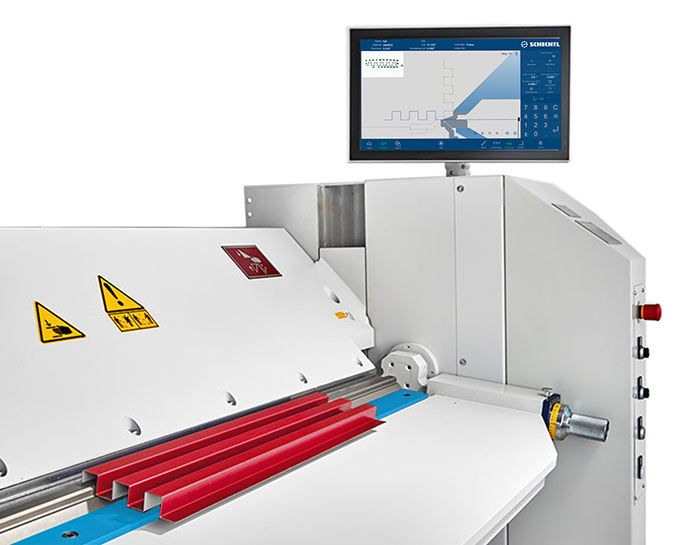

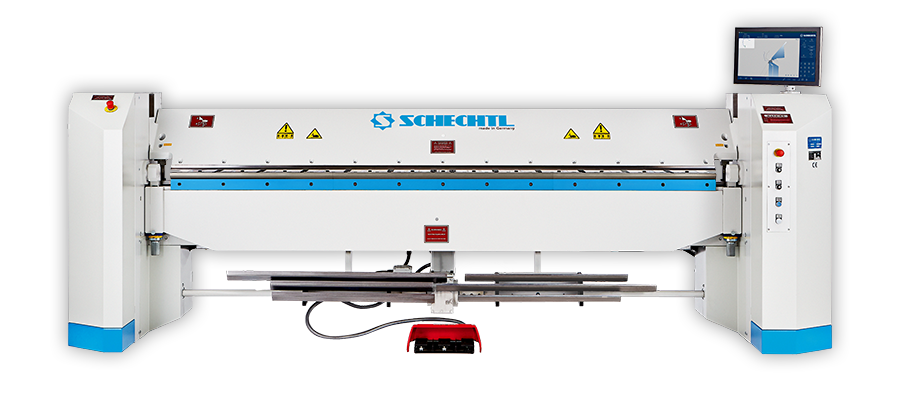

You might know that MetalForming LLC's Schechtl MAX is one of the most popular selling metal folders in North America, but that was before you knew about the MAX-F and MAX-I. Now everything contractors love about the Schechtl MAX has been thoughtfully re-engineered to bend faster, hem better and increase flexibility. That’s right, now the legendary strength of the MAX has been improved with a redesigned clamping, bottom and folding beam. Revisions to equipment take time and many more iterations, but the MAX-F and MAX-I both sport some major redesigns that make the machines game changers.

Here are just a few of the changes that have taken the MAX-F and MAX-I to the next level:

- The clamping and bottom beam is stiffer for superior hemming.

- More clearance between the gauge table and the clamping beam.

- The folding beam, driven by the new electric direct-drive system, is more efficient, with faster bending speeds and better bending consistency.

- Newly designed dual servo-drive gauge system for lightning-fast gauging.

- A taller bed height which means no more bending over to insert material.

Read on to learn more about the MAX-I and MAX-F machines and what makes them some of the best machines in the industry.

MAX-I

With a reimagined clamping beam dimension, there is even more free space under the clamping beam totaling 2.4” and increasing folding flexibility with larger profiles. It also uses a powerful 14-gauge MAB clamping beam structure for better hemming results. Additionally, the legendary strength is now improved upon with better material stiffness throughout.

The new welded machine side frames have a modern, sleek design with the latest safety regulations incorporated in the electrical cabinet, and a new bed height is taller and more ergonomic to decrease bending over to insert material.

MAX-F

The MAX-F has all the latest and greatest features of the MAX-I, plus new F-Geometry – making it the first of its kind in a short folding machine. The F-Geometry creates more free space taking the already versatile MAX to a whole new level, this gives the MAX-F greater flexibility, and contractors who already have a folder are upgrading to the MAX-F because of its speed, better hemming and ease of use. The MAX-F decreases the need to push against deeper profile geometries while being folded. Now, bending hat channels, corrugations, vented ridges, pitch correct drip edges and bigger J's is easier than ever.

iFold control

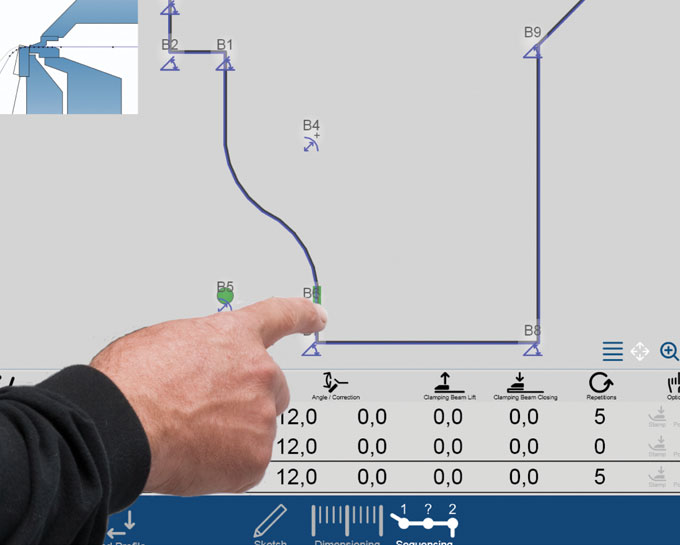

Both the MAX-I and MAX-F are equipped with iFold touch screen interface allowing you to drag and draw parts in real time, creating the actual dimensions as you go. The interface tells you when to flip, rotate and move the part to finish it, helping to decrease production prep time and folding error.

You can also use the J-Bend app for mobile programming to save you time back at the shop. The iFold program Explorer function allows operators to organize and store parts in an endless number of ways: part number, job name, project name or number. Not to mention the program comes with a massive core parts library filled with industry standard parts. Besides linking to the mobile app, the control can network to your office computers, multiple machines or with MetalForming LLC for remote support.

Warranty

Includes an industry-leading three-year parts and one-year labor warranty. With the legendary reliability of Schechtl, and the largest technical staff of MetalForming, you’re getting a machine that’s backed by industry experts.

Learn more about MetalForming LLC. in their directory or visit metalforming-usa.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In