MetalForming LLC

MetalForming LLC represents your One Partner, Trusted Expert in sheet metal folding, forming, and fabrication solutions for architectural and advanced precision applications. For more than 25 years we have provided solutions from the most innovative and best-in-class global machine and software partners. Our superior after-sales service and technical support for companies of all sizes and experience levels is bolstered by our large stock of machines and parts inventory for expedited delivery. The Manufacturers that we exclusively represent in North America are: Jorns, Krasser, Schechtl, Schlebach, Schroeder, Stolarczyk, Bendex, Boeckelt Tower.

MetalForming Machines LIVE

In this MetalTalk, Heidi J. Ellsworth sits down LIVE with the experts at MetalForming including President & CEO Stephen Gosk, Business Development Director Chad Rowe, Executive VP Precision Sales David Prokop and Executive VP Operations Martin König to talk about metal forming machinery. They will be live at the MetalForming headquarters showing their high-performance metal fabrication machinery throughout MetalTalk. The group talks about the technological evolution and precision operations of metal fabrication from leading manufacturers Jorns, Krasser, Schechtl, Schlebach, Krasser, Stolarczyk, Schröder, Boeckelt and Bendex, all of whom they exclusively distribute in North America. Don’t miss this unique look at the showroom and expertise of MetalForming, LLC.

Revolutionize your Shop with Conical Bending

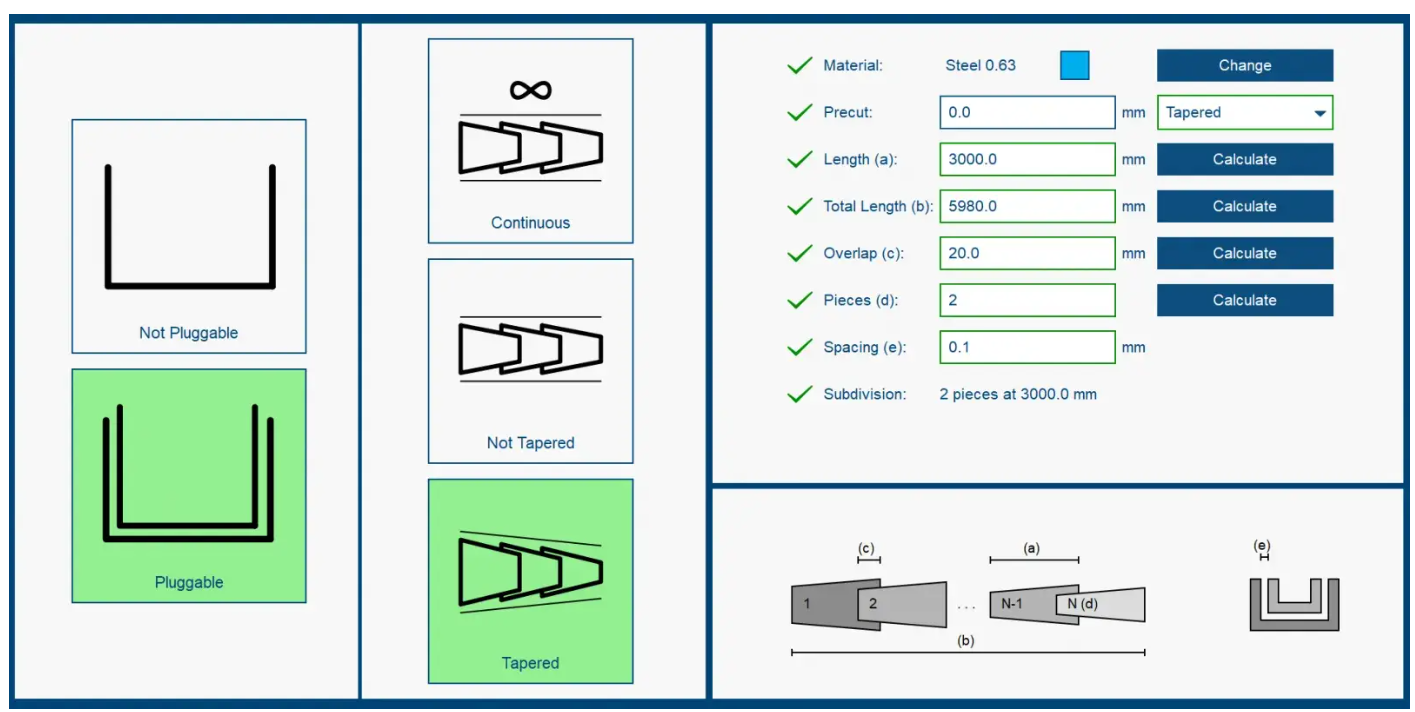

Become the expert in conical bending! Did you know some of the older Schechtl machines can be upgraded to include conical bending? The Schechtl back gauge for conical bending simplifies the production of numerous sheet metal profiles. Pluggable profiles and flashings can now be produced accurately and efficiently. Time-consuming processing steps on the construction site are eliminated. The back gauge is thus ideal for applications where edge lines are required that do not run parallel. For example, for gutters, eaves plates and covers.

Say goodbye to the hassle of producing various sheet metal profiles as pluggable profiles and flashings can now be crafted with precision and efficiency. By eliminating time-consuming steps on-site, it's a great solution for applications that require non-parallel edge lines. Think gutters, eaves plates, and covers – all made easier with conical bending. The conical back gauge is available for the following motorized swivel bending machines with CNC control: MAX, MAX-F, MAB, MAF, MAZ, & MAE.

Learn more about Conical Bending.

Revitalize Your Workshop: Upgrade Your Schechtl Folder with Cutting-Edge Features

As a longstanding MetalForming customer, you are eligible for best pricing on maintenance contracts and upgrading your current machines. Increase efficiency by revitalizing your existing Schechtl machines. Don't forget, MetalForming offers Preventive Maintenance Contracts, and we gladly accept trade-ins.

-

New Hardware, including monitors, safety features and increased functionality.

-

New Software provides you with more functionality, a better user experience.

Hardware upgrades for optimal performance:

-

Improved Functionality: Replace your old electromechanical components have with cutting-edge technology for enhanced performance.

Improved Functionality: Replace your old electromechanical components have with cutting-edge technology for enhanced performance. -

Enhanced Display: Get a new monitor for improved visibility and usability

-

Spare Parts Availability: Modernized equipment will have fewer breakdowns, and it is more likely you can quickly find the spare parts you need.

Software upgrades to increase efficiencies:

-

Benefit from current software featuring 3D capabilities, profile management, CNC freehand drawing, and significantly improved graphics mode.

-

Network Integration: Effortlessly integrate the machine into your existing network for streamlined operations.

-

Improved Connectivity: Our machine is now WiFi-capable, offering greater convenience and flexibility.

Contact us for more details today!

Not ready for new?

As a longstanding MetalForming customer, you are eligible for best pricing on maintenance contracts and upgrading your current machines. We offer a wide range of metal forming machinery services to meet the individual needs of our diverse customer base. Our technicians come from a variety of industrial and military backgrounds with extensive experience and training. The technicians are trained in the factories where the machines are built so you can be assured you are in the most capable hands in the industry.

-

Upgrade your hardware and/or software for increased efficiencies. Get new monitors, controllers and/or software for better usability and connectivity.

Upgrade your hardware and/or software for increased efficiencies. Get new monitors, controllers and/or software for better usability and connectivity. -

Keep your Schechtl equipment in top shape with experienced maintenance professionals on staff at MetalForming.

Don't forget, MetalForming has your back -- we offer Preventive Maintenance Contracts and we gladly accept trade-ins.

MetalForming is the exclusive distributor of Schechtl metal bending, cutting, and profiling equipment in North America.

Check out our Upgrade and Maintenance services!

Technical Services

At MetalForming, we stand ready to support our customers, no matter what it takes. Our technical services team, which represents 50% of all MF employees, were handpicked for their expertise and their dedication and commitment to customer satisfaction. They have been highly trained both here in the US and in our vendors’ factories all over the world. Your machines are also backed by the servicing organizations of all of our vendor partners. We offer:

- Traditional onsite installation, training, maintenance and repair services, technical support via email, over the telephone or in person. The sophistication of some of our machines even allows for them to be serviced over the internet to save you time and money.

- A parts inventory second to none in the industry. We make it our business to get our customers most of the parts they need by the next day.

Learn more about our technical services.

Consulting Services

Because we have such a deep level of knowledge on how these machines are used we can help customers find the right machine for the job, figure out the best way to form parts and develop plans to improve operations for better efficiency. We provide counsel on modernizing and automating sheet metal manufacturing operations to improve our customers’ bottom line. Our services include: production optimization evaluations, strategic planning, real-time monitoring and reporting, custom software development and more.

Latest Promotions and Rebates

Revolutionize your Shop with Conical Bending

Did you know some of the older Schechtl machines can be upgraded to include conical bending? The Schechtl back gauge for conical bending simplifies the production of numerous sheet metal profiles. Pluggable profiles and flashings can now be produced accurately and efficiently. Time-consuming processing steps on the construction site are ...

View Promotion

Not ready for new?

As a longstanding MetalForming customer, you are eligible for best pricing on maintenance contracts and upgrading your current machines. We offer a wide range of metal forming machinery services to meet the individual needs of our diverse customer base. Our technicians come from a variety of industrial and military backgrounds ...

View Promotion

Latest Podcasts

MetalForming Machines LIVE

In this MetalTalk, Heidi J. Ellsworth sits down LIVE with the experts at MetalForming including President & CEO Stephen Gosk, Business Development Director Chad Rowe, Executive VP Precision Sales David Prokop and Executive VP Operations Martin König to talk about metal forming machinery. They will be live at the ...

Listen to the Podcast

Sheet Metal Shops: Why and How

Join us for a stimulating episode of Coffee Conversations, sponsored by Metalforming, where we explore the ins and outs of starting your own sheet metal shop and adding metal roofing to your company’s offerings. Whether you're a seasoned contractor looking to diversify your services or a fan of metal roofing, ...

Listen to the Podcast

New Fabrication Technology for 2024

In this MetalTalk, Karen Edwards visits with Chad Rowe, Ken McLauchlan and Stephen Gosk of MetalForming to discuss new fabrication technology must-haves for 2024. As sheet metal shops, contractors and fabricators look at producing the metal building products the market demands, MetalForming is providing the machinery to do it. They ...

Listen to the Podcast

Latest Webinars

Sheet Metal Shops: Why and How

Join us for a stimulating episode of Coffee Conversations, sponsored by Metalforming, where we explore the ins and outs of starting your own sheet metal shop and adding metal roofing to your company’s offerings. Whether you're a seasoned contractor looking to diversify your services or a fan of metal roofing, ...

Watch the Webinar

Best Practices – General Maintenance on Metal Forming Equipment Machinery

The Metal Forming Equipment Council (MFEC)/Rollformer Council has partnered with a collaboration of machinery OEMs to provide a structured outline of the benefits of proper general maintenance schedules for machinery. Fabricating accurate and aesthetically acceptable metal trim and panels is essential to the success and efforts of many other supply ...

Watch the Webinar

Latest Lunch & Learn

The Influence of Metal Coil Processing on Roofing

Heidi J. Ellsworth is joined by MetalForming Business Development Director Chad Rowe to explore the evolution of metal coil processing and its influence on roofing. From the basic slasher system technology of yesterday to the advanced, fully automated coil warehouses we see today, they talk about how new technologies ...

Watch the Webinar

Options for Folding and Breaking Metal

In this RoofersCoffeeShop Lunch & Learn, Heidi J. Ellsworth sits down with Ken McLauchlan, MetalForming Vice President Architectural Sales and Chad Rowe, MetalForming Outside Sales to talk about the various options for folding and breaking metal. With the metal roofing and siding markets growing every year, contractors are looking for ways to ...

Watch the Webinar

Read Listen Watch - Educational Content

Enhancing Safety in Sheet Metal Bending

In this MetalTalk Karen Edwards is joined by MetalForming LLC’s Business Development Director, Chad Rowe, for a jam-packed conversation about enhancing safety within the sheet metal bending industry. With manufacturing consistently ranking among the top industries for reported injuries, he explores how light curtain safety systems can significantly reduce ...

View Content

MetalForming Machines LIVE

In this MetalTalk, Heidi J. Ellsworth sits down LIVE with the experts at MetalForming including President & CEO Stephen Gosk, Business Development Director Chad Rowe, Executive VP Precision Sales David Prokop and Executive VP Operations Martin König to talk about metal forming machinery. They will be live at the ...

View Content

New Fabrication Technology for 2024

In this MetalTalk, Karen Edwards visits with Chad Rowe, Ken McLauchlan and Stephen Gosk of MetalForming to discuss new fabrication technology must-haves for 2024. As sheet metal shops, contractors and fabricators look at producing the metal building products the market demands, MetalForming is providing the machinery to do it. They ...

View Content

Latest Classifieds

Revolutionize Your Shop With Conical Bending

Did you know some of the older Schechtl machines can be upgraded to include conical bending? The Schechtl back gauge for conical bending simplifies the production of numerous sheet metal profiles. Pluggable profiles and flashings can now be produced accurately and efficiently. Time-consuming processing steps on the construction site are ...

View the Classified

Not ready for new?

As a longstanding MetalForming customer, you are eligible for best pricing on maintenance contracts and upgrading your current machines. We offer a wide range of metal forming machinery services to meet the individual needs of our diverse customer base. Our technicians come from a variety of industrial and military backgrounds ...

View the Classified

Buy Online

Did you know some of the older Schechtl machines can be upgraded to include conical bending? The Schechtl back gauge for conical bending simplifies the production of numerous sheet metal profiles. Pluggable profiles and flashings can now be produced accurately and efficiently. Time-consuming processing steps on the construction site are ...

Read More

MetalForming is having a Spring Special on new Schechtl Machines!

Sign up for a new Schechtl Bender June 30, 2024, and save about 10% off the complete package:

Free installation at your facility

Free training for your staff

The latest hardware and software, including the Schechtl back gauge for conical bending.

Do more. Find ideas ...

Read More

As a longstanding MetalForming customer, you are eligible for best pricing on maintenance contracts and upgrading your current machines. We offer a wide range of metal forming machinery services to meet the individual needs of our diverse customer base. Our technicians come from a variety of industrial and military backgrounds ...

Read More

Latest Videos

The Weekly Blend - Episode 148 with MetalForming!

Join us every week to learn the latest news in the roofing, metal and coatings industry.

The 148th episode of The Weekly Blend is live! This week, Chad Rowe, technical sales leader of MetalForming, joins The Coffee Shops’ President Heidi Ellsworth and COO Karen Edwards for the latest episode of our ...

View Video

The Weekly Blend - Episode 143

Join us every Friday to learn the latest news in the roofing, metal and coatings industry.

The 143rd episode of The Weekly Blend is live! Join the Coffee Shops’ President Heidi J. Ellsworth and COO Karen Edwards for the latest episode of this Coffee Shop original web series.

This week, Heidi and ...

View Video

The Weekly Blend - Episode 142

Join us every Friday to learn the latest news in the roofing, metal and coatings industry.

The 142nd episode of The Weekly Blend is live! Join the Coffee Shops’ COO Karen Edwards and Multimedia Manager Megan Ellsworth for the latest episode of this Coffee Shop original web series.

Tune in to this ...

View Video

View Full Gallery