Five Benefits of a Spray Foam Roof System

By Will Lorenz, General Coatings.

As roofing contractors, you know that the main goal of any roofing project is to avoid water penetration.

Mitigating damage from a leaky roof is expensive and time-consuming. To protect their asset, commercial building owners need a roofing system that is cost-effective, easy to maintain and durable.

Typically, commercial buildings have low slope roofs because they are economical to construct and maintain when compared to the cost of a similarly sized pitched roof. Low slope roofs are easier to inspect and also increase usable space. However, since these roofs cover large, flat surface areas, they present some challenges. For example, they are prone to the building’s natural expanding and contracting, and ponding. A spray foam roofing system addresses these issues and provides other benefits to commercial buildings with low slope roofs. Let’s examine a few.

Seamless and Monolithic. Seams and penetrations are the primary sources of leaks in roof systems. Weather is a constant battle between warming and freezing temperatures and wreaks havoc on a roof’s membrane. The expanding and contracting of the building are destructive forces that can cause shrinkage, pull the membrane away from walls and penetrations, and separate the membrane’s seams. However, an insulated seamless spray foam roofing system withstands the structure’s expansion and contraction, fully-adheres to the deck, self-flashes around irregular penetration, and remains waterproof for its anticipated life expectancy, protecting the facility from harsh weather conditions.

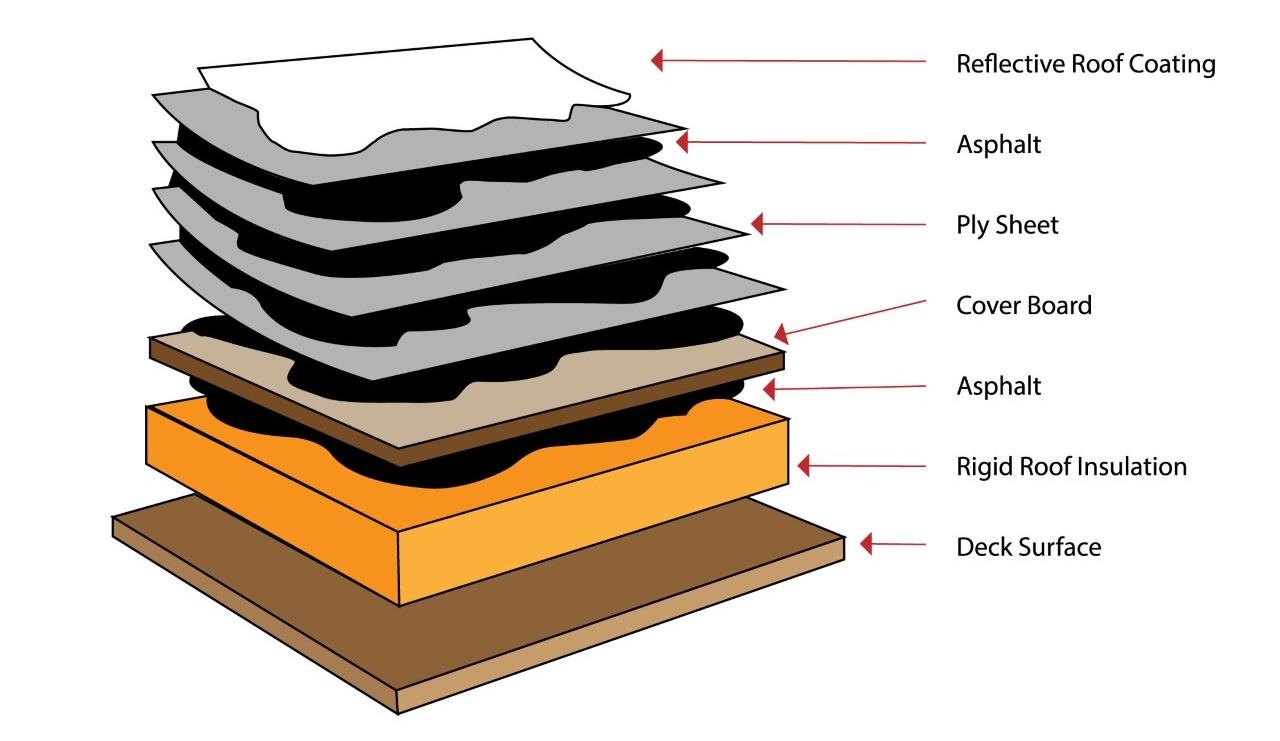

Versatile. Spray foam is often thought about only for a retrofit roofing project, but it also is a beneficial solution for new commercial construction. As you know, in a traditional roofing system, a deck is installed first, then insulation, protection boards, and finally the membrane or covering is applied. These are at least four layers and involves a tremendous number of labor hours, not including the time-consuming tasks of fastening and adhering. However, the field-applied spray foam roof system can be installed directly to the roof deck and is an all-in-one, effective insulation with UV reflective coating that greatly reduces labor and energy costs.

Example of traditional build-up roofing system's many layers.

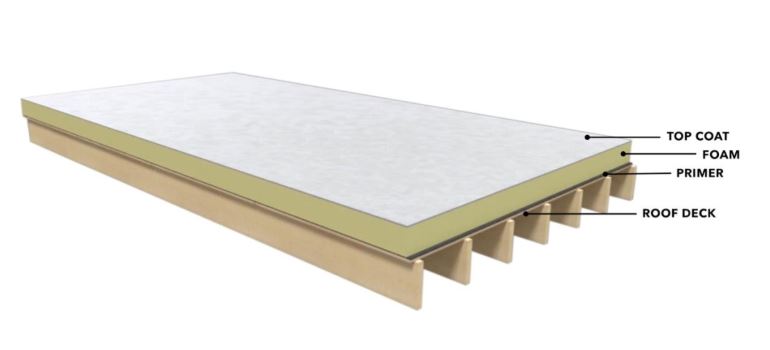

Example of a spray foam roofing system applied to a roof deck

Illuminates Ponding. Most low slope roof systems are designed with a slight incline of ¼” - ½” per foot to encourage the flow of water towards a drainage system. However, as water accumulates on a low slope roof it finds a weak spot to penetrate into permeable materials or seams that aren’t well-sealed. As water accumulates, it deteriorates most traditional roofing materials: adhesives in single-ply roof systems lose their grip; steel equipment supports are corroded; oil solvent components of roofing asphalts seep into the water, leaving the remaining membrane brittle, cracked and leaking as the pond grows, accelerating the roof’s aging. Ponding also increases the deadload on the roof and, unfortunately, remains until the water evaporates.

Conversely, since roofs may not be level, installing a spray foam roof system fills in uneven areas ensuring a natural slope that directs water to the drain and mitigates ponding. Because spray foam is applied directly to the roof surface rather than being prefabricated and then put on the roof, it can be installed thicker in some parts and thinner in others. This allows for filling in the known ponding areas and for the rain water to flow to the channels and drains more effectively, while also reducing deadload.

Easy Application. The spray primer, foam and roof coating as a retrofit system can be installed with minimal interruption to a facility because tear-off of the existing roof is usually not needed, saving building owners time and money. After cleaning and preparing the existing roof, this system can be field-applied by professionally trained contractors spraying a continuous, insulated and waterproof foam membrane over the existing substrate, whether it’s built up, metal, membrane or modified bitumen. The final process is the application of a top coat. And unlike traditional roofing systems, spray foam effectively seals difficult penetrations, parapet walls, HVAC stands, round vents and raised skylights.

Easy Maintenance. This virtually maintenance-free system includes a solar reflective coating with embedded granules that increases the roof’s surface durability. However, should there be a puncture, it can easily be repaired with roof sealant, while the facility remains fully operational. A spray foam roofing system is actually renewable because it can be recoated with additional roof coating when the system comes to its surface life in 10-20 years. It’s the only roofing system that is designed to be sustainable and to last the lifespan of the building.

Conclusion

As a trade partner you are often called upon to provide a solution that is best suited to meet each project’s unique roofing challenges. I hope that the information provided here and in my previous articles helps you better understand the many benefits, such as easy application and maintenance, and versatility that spray foam roofing systems offer commercial building owners’ new construction and retrofit projects.

As a project member, you strive to implement best practices and provide better value to clients. Utilizing a spray foam system on low slope commercial roofs helps you achieve these goals.

Learn more about General Coatings in their RCS directory.

Will Lorenz is Vice President of Sales with General Coatings and may be reached at will@generalcoatings.net or (949) 466-8552. Over his 33-years in the roofing and polyurethane foam industry, Will has received numerous awards and recognition. He is currently president of the Roof Coating Manufacturers Association, a member of NRCA and serves on the board of directors for the past two years for the Spray Polyurethane Foam Alliance board of directors. When not focused on roofing, Will enjoys watching the Chicago Cubs and Blackhawks, spending time with his family and attending church, and taking his pit-bull mix, Mack, for long walks around his California neighborhood.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In