The TUBOS vent stack extension solution

By TUBOS.

Historically, vent pipes were flashed with lead boots or with a no-hub connector, but today there is a faster and easier way!

Plumbing vent pipes are an integral part of a building’s plumbing system and, more specifically, its drainage system. Vent stacks are designed to work along with a building’s drain pipes, by allowing air into the plumbing system, which allows greywater and waste to flow freely out of the building and allows sewer gasses and odors to properly escape out of the building.

Plumbing vent pipes are an integral part of a building’s plumbing system and, more specifically, its drainage system. Vent stacks are designed to work along with a building’s drain pipes, by allowing air into the plumbing system, which allows greywater and waste to flow freely out of the building and allows sewer gasses and odors to properly escape out of the building.

In addition, plumbing vent stacks are required by code to be a certain height over the surface of the roof, typically 6-inches, but many contractors prefer 8-inch heights. When insulation is added on a re-roofing project to meet R-value requirements the vent stack height is effectively reduced by the thickness of the added insulation, and the vent stack height falls out of code compliance.

The International Plumbing Code (IPC): This requires plumbing vent pipes to extend vertically at least 6-inches (152 mm) above a roof, per Section 905.5, "Vent Connections and Grades." Additionally, vent pipes must be at least 12-inches (305 mm) away from a vertical surface. In locations known for snow, the vent pipe needs to be at least 2-inches (51 mm) in diameter and 12-inches (305 mm) inside an insulated area of a building before extending through the roof. Vents in these locations also should extend 24-inches (610 mm) above the roof.

The International Plumbing Code (IPC): This requires plumbing vent pipes to extend vertically at least 6-inches (152 mm) above a roof, per Section 905.5, "Vent Connections and Grades." Additionally, vent pipes must be at least 12-inches (305 mm) away from a vertical surface. In locations known for snow, the vent pipe needs to be at least 2-inches (51 mm) in diameter and 12-inches (305 mm) inside an insulated area of a building before extending through the roof. Vents in these locations also should extend 24-inches (610 mm) above the roof. 2010 Florida Building Code, Plumbing 904.1 Roof extension: All open vent pipes that extend through a roof shall be terminated at least 6 inches (152 mm) above the roof and not less than 2-inches (51 mm) above the invert of the emergency overflow, except that where a roof is to be used for any purpose other than weather protection, the vent extensions shall be run at least 7- feet (2.1 m) above the roof.

2010 Florida Building Code, Plumbing 904.1 Roof extension: All open vent pipes that extend through a roof shall be terminated at least 6 inches (152 mm) above the roof and not less than 2-inches (51 mm) above the invert of the emergency overflow, except that where a roof is to be used for any purpose other than weather protection, the vent extensions shall be run at least 7- feet (2.1 m) above the roof.

Historically, on commercial roofs, vent pipes were flashed with lead boots below, or with a no-hub connector. However, today there is a faster and easier way for commercial roofers to extend a vent stack that meets code and performs without allowing any moisture into the roaofing assembly.

Pre-engineered and patented

Pre-engineered and patented

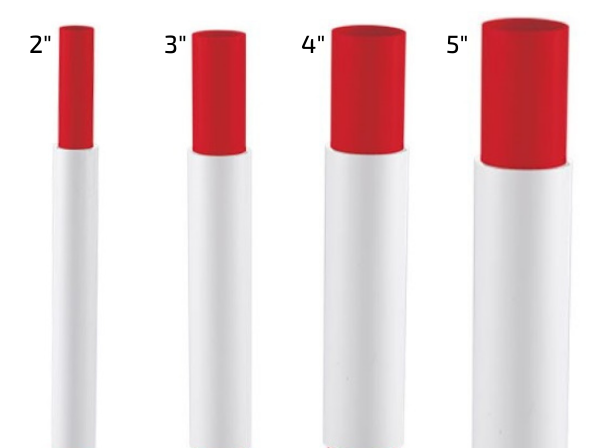

Tubos pipe extensions are available in 2-, 3-, 4- and 5-inch diameters to accommodate most common vent stack sizes, and are fully compatible with both cast iron and PVC vent stacks. Each Tubos unit has a six-inch internal splice sleeve that fits down the inside of the existing vent stack, that prevents water and moisture from leaking into the roofing assembly. The outer sleeve of the Tubos unit sits on top of the existing vent stack and can be flashed with a variety of materials and methods including thermoplastic or thermoset boots, a hose clamp and caulk.

Once installed, any water that seeps across the top of the original vent stack will flow harmlessly into the vent stack or plumbing system and not into the commercial roofing assembly. “From time to time we get questions about the potential air-flow reduction,” said Kevin Morris, CEO of Tubos. “But honestly, a Tubos unit does not impact the air flow as much as a lead boot flashing does, and those have been used for decades. Furthermore, the reduction in the vent stack with a Tubos unit is not only very minor, but the insert sleeve is only 6-inches long, which in the total plumbing system is miniscule. We’ve never had a call back or warranty issue as a result of a lack of air in the system, and in fact, we’ve never had a warranty issue for moisture in the roofing assembly either.”

Some contractors think no-hub connectors are faster and cheaper. However, there are several potential issues with no-hub connectors. “For one, the diameter of the PVC pipe available is often not an exact fit for the existing vent stack,” said Morris, “and they are not guaranteed to be watertight. In fact, if the applicator does not use a tourque wrench to tighten the clamp to the proper setting, they are much more likely to leak.” In addition, no-hubs take longer to install, usually require a larger boot for flashing, and are generally not available through roofing distributors, meaning that the contractor has to send someone to the hardware store to get the materials, which adds time and labor.

By contrast, Tubos units are designed to help roofing contractors do more with less. They are fast and simple to install, typically take less than three minutes to install, and can be a real productivity enhancer on the roof, particularly if there are multiple vent stacks to address. Tubos units are installed in four easy steps. Just measure, cut, seal, and flash and you’re done. Plus, each 28-inch-long unit can be cut and used to extend two pipes, and extensions can be up to 16-inches long. They are ideal for use where a tapered system is added, or a new lightweight insulating concrete deck is being poured.

Learn more about TUBOS in their Coffee Shop directory or visit tubos.biz.

Get your first TUBOS for less and see the quality for yourself.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In