The Importance of Preventing Leaks in Mass Timber Roofs: Mitigating Moisture Risks for Long-term Durability

By SMT Research.

Understand the risks of water exposure in mass timber construction and effective prevention strategies.

As time goes on, mass timber, particularly the use of cross-laminated timber (CLT), is used more and more in construction. Understandably so, as it's a fantastic sustainable and cost effective alternative to traditional building materials like concrete and steel. SMT often gets questions about moisture in mass timber, so we took the time to talk about our view for preventing moisture damage in mass timber roofs.

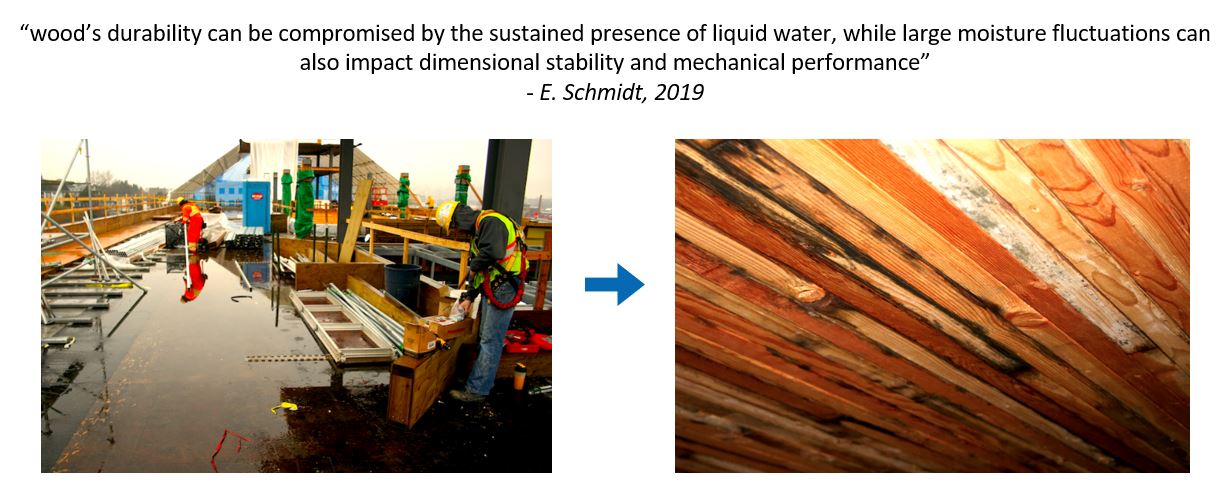

While using a new material can be ground breaking, as with any construction material, it's important to understand the potential risks associated with mass timber, particularly when it comes into contact with water. Water is a critical factor in the life cycle of wood, as it can both facilitate and impede the growth and decay processes. When wood is exposed to water for long periods of time, it can absorb moisture and become saturated, leading to potential issues that will compromise the structural integrity of the building.

One of the main risks associated with mass timber construction remaining wet for extended lengths of time is dimensional instability. When wood is exposed to water, it can swell and expand, leading to potential issues such as warping and splitting. This can affect the structural integrity of the building and potentially compromise its safety. Additionally, if the wood is not allowed to dry properly, it may shrink and contract over time, leading to potential issues such as cracking and buckling.

There is also the potential for rot and decay that must be considered when working with mass timber. When wood is exposed to water and other environmental factors, it can become a breeding ground for fungi and other microorganisms that break down the wood fibers. This can compromise the strength and durability of the building, potentially leading to costly repairs and even structural failure.

Mold growth is another potential issue associated with mass timber construction remaining wet for long periods of time. Mold thrives in damp, humid environments, and can lead to potential health issues such as respiratory problems and allergies. Mold growth can also compromise the structural integrity of the building by breaking down the wood fibers and weakening the building components.

If we were to illustrate mass timber and what happens when it gets wet, we'll use what happens to wet clothes left in a pile as an example.

Both materials can suffer from mold growth when exposed to water for extended periods of time. Wet clothes left in a pile on the floor can take a long time to dry out, as the moisture is trapped between the layers of fabric, and there is little airflow to facilitate drying. This is similar to wet CLT, which can also trap moisture within the layers of the panel and prevent proper drying.

To mitigate the risks associated with mass timber construction remaining wet for long periods of time, it's important to follow proper construction and maintenance practices, which includes monitoring the building for moisture using sensor technology. During the construction process, it's crucial to protect the CLT panels from moisture and ensure that they are properly sealed and ventilated. This may involve using leak detection tools like Digiscan to inspect the waterproof membranes, installing drainage systems, and using proper flashing and sealing techniques to prevent water infiltration.

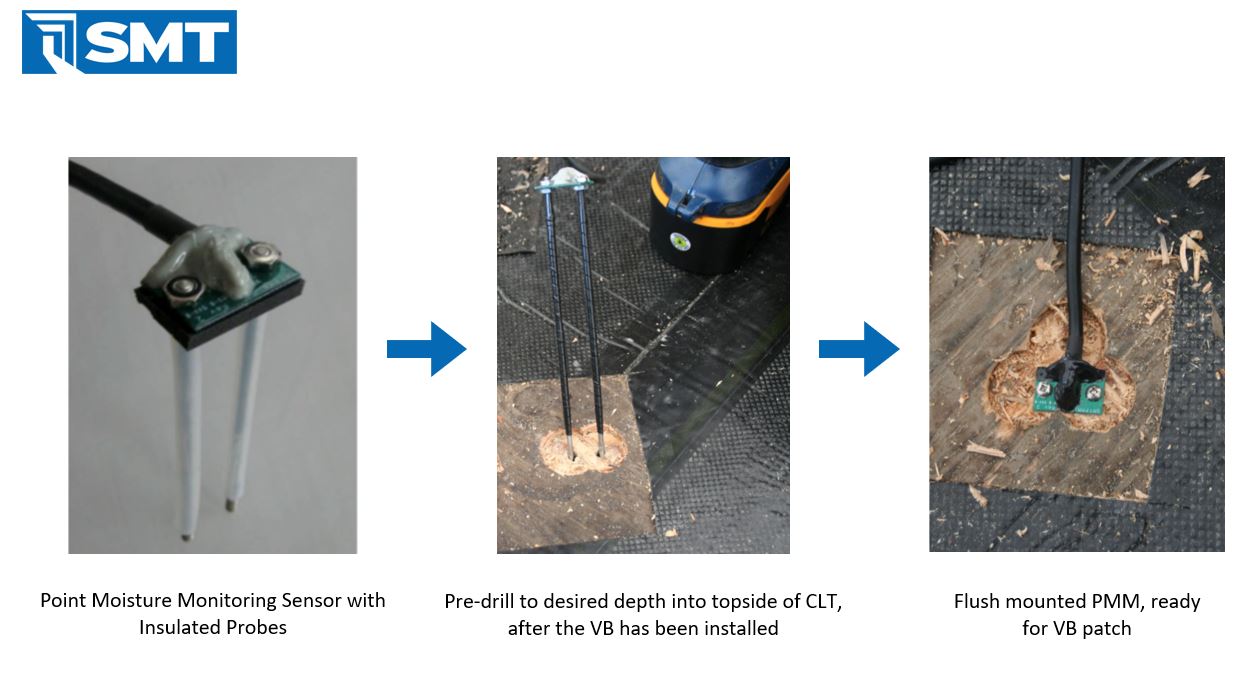

After the building is completed, it's highly important to regularly inspect the building components for

signs of moisture damage. This can be difficult to do without compromising the design of the building, which is why SMT recommends installing FutureCast and point moisture monitoring sensors to monitor for any signs of damage that should be addressed immediately. Should a problem arise, the compiled data from the sensors will be sent directly to the building owner or manager, giving them time to make repairs before the damage becomes too great. By leaving sensors in the mass timber, we can monitor the wood for signs of damage for the entire lifetime of the building.

Although mass timber construction has numerous advantages, it's crucial to comprehend the possible hazards that could arise from prolonged exposure to water. To guarantee the building's long-term durability and safety, appropriate construction practices and monitoring the wood for moisture can be implemented to mitigate these risks.

If you would like to learn more about moisture in mass timber, or if you have a mass timber project

coming down the pipeline, we host a lunch and learn session surrounding this topic.

Contact us here, to book yours today!

Learn more about SMT Research in their Coffee Shop Directory or visit www.smtresearch.ca.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In