The Art of Replacing Structural Metal Deck

By Lauren White, RCS Reporter.

Industry professionals share their expertise about metal deck.

Metal deck suppliers were asked to share common questions they encounter as well as the ways they help roofing contractors meet their metal deck needs for an article written by Chris King from Roofing Magazine. Nick V. Polizzi, president of A.C.T. Metal Deck Supply, was one of the suppliers interviewed. A contractor and roof consultant were also consulted to get their perspectives regarding metal decks and to share their recommendations for successful re-roofing projects.

According to Polizzi, some of the most frequently asked questions A.C.T. Metal Deck Supply receives from roofing contractors include, “‘What is this existing deck?’ ‘What do we use if we can’t match it exactly?’ and ‘Can I get it today?’ That is, do we have it in stock.” Matt Weiss, president of O’Donnell Metal Deck, is also familiar with these types of questions. “I do the same kind of dance every day,” Weiss says. “I hear, ‘Hey, we’re up on a roof and need some deck.’ I say, ‘What kind?’ Often there is just silence.”

Regarding roof inspections and safety precautions, the experts recommend getting as much information as possible at the jobsite. Safety is always a concern for roofing professionals, even during the inspection stage. John D’Annunzio, president of Paragon Roofing Technology, notes, “During the remedial roof removal process, the metal deck should be inspected on a daily basis.” D’Annunzio and Mike Horwath, Mid-Atlantic Regional Manager for CentiMark, agree that building owners and facility managers can be excellent resources for obtaining documentation and as-built drawings, in addition to knowing the history of the building regarding leaks, integrity issues and problem areas.

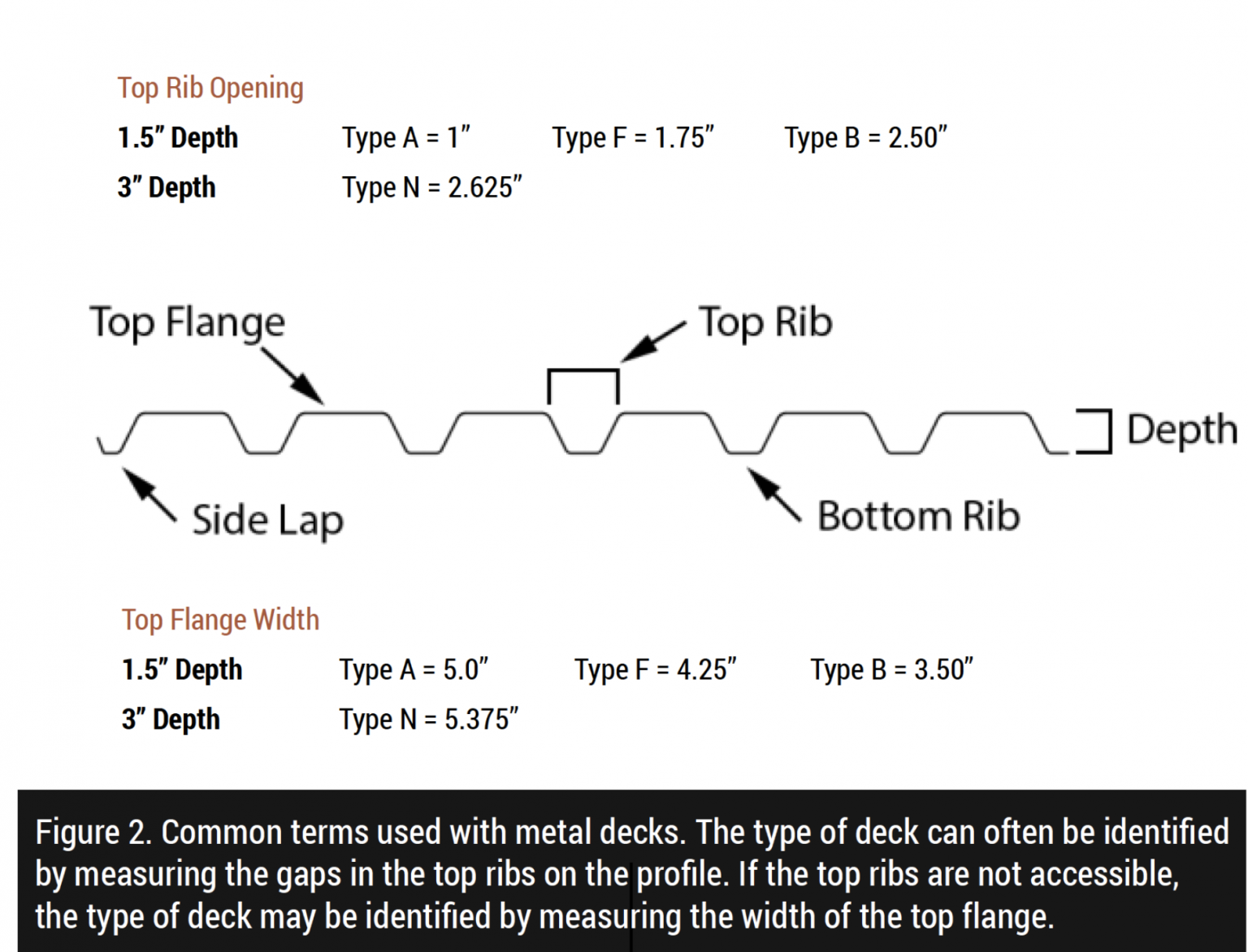

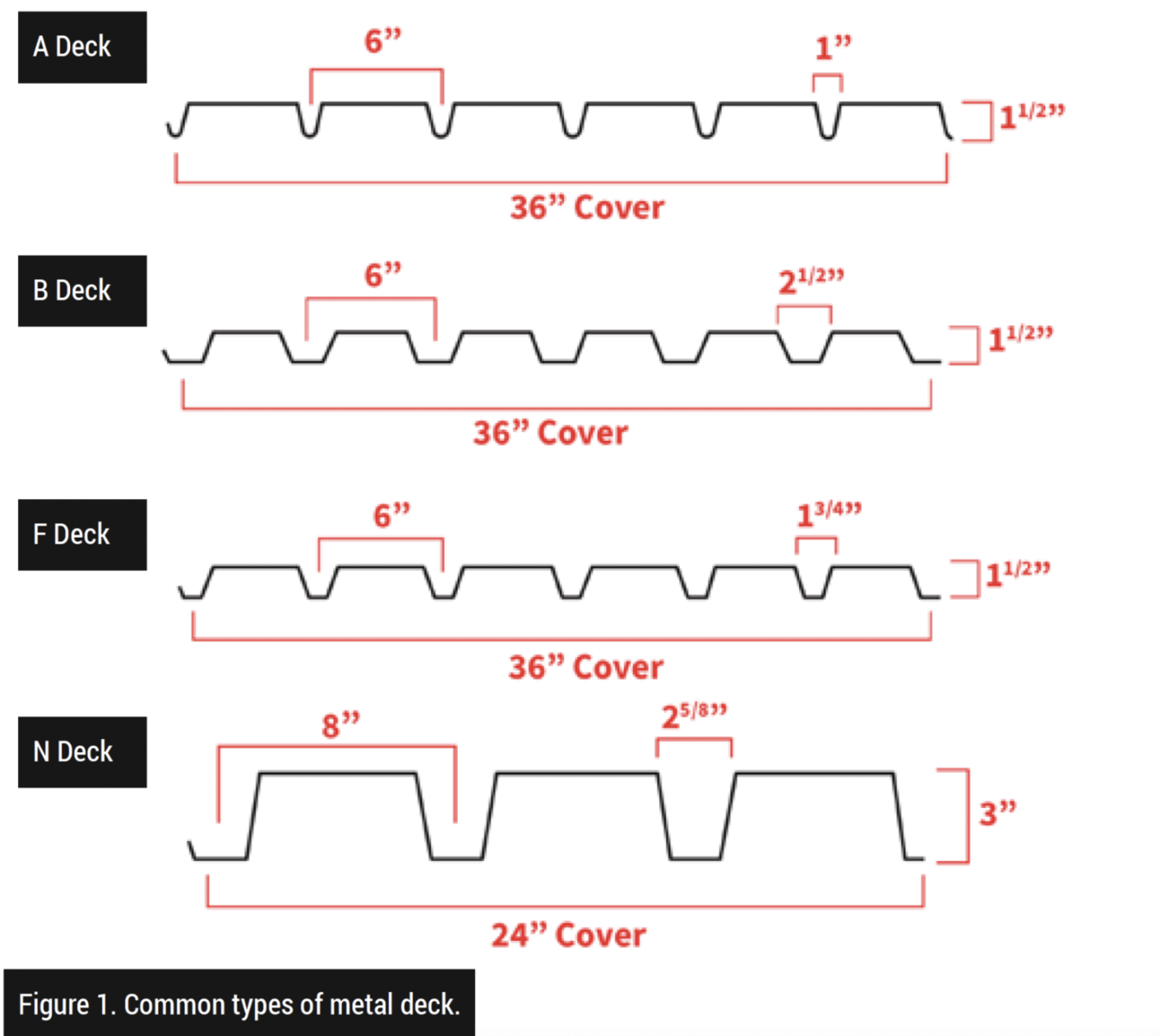

One part of the reroofing process is identifying the existing deck. The experts share important information regarding the differences in metal deck and how to determine what kind is needed for the project at hand. In the construction documents, if the type of deck used isn’t available, the type, gauge and finish of a deck need to be identified at the site. The type of deck is based on its profile, and each profile has its own specific measurements. The three most commonly used types are A, B and F. “The changes are in the shape, and the shape creates a different design strength. A-22 is not the same strength as B-22,” Polizzi explains. The article also explains how each profile of metal deck differs, based on measurements, finishes and gaps in the ribs on the profile.

In order to help contractors plan ahead and avoid lead times when ordering new products, metal deck suppliers, like A.C.T. Metal Deck, keep multiple profiles, gauges, finishes and lengths in stock at all times. Polizzi notes that suppliers are available to help contractors discover ways to maximize their efficiency. One way some of Polizzi’s customers have done this is by keeping their own stock of B deck for when they have an emergency or a tear-off. In doing this, it allows them to start on the project right away while they wait for their additional supplies from A.C.T Metal Deck.

“In the past, roofers used to avoid anything to do with metal deck replacement because they often couldn’t get what they wanted,” according to Polizzi. “Today, we have helped these roofers create a new profit center because they know now they can go after that work and they can count on us to be there for them when they open up a roof.”

Read the full article at Roofing Magazine to learn more about replacing metal deck in re-roofing applications.

For more information, visit www.metaldecksupply.com or 800-894-7741.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In