SBS Modified Asphalt Assures Roof Durability

By Colin Sheehan, RCS Reporter.

Advantages of SBS include heightened flexibility and easy maintenance.

In contrast to older buildings, new light-weight structural materials compose the majority of buildings we see today. MBTechnology recognized that modern roofing systems had to develop towards heightened durability due to increased substrate movements. Substrate movements occur when less dense materials are used to construct the internal composition of a building and enhanced durability prevents the roof and building from having costly structural problems.

Because of this shift towards lighter-weight structural materials, durability became a necessary characteristic of all roofing systems. Luckily, a roof’s durability can be assured through precise planning, accurate specification and through choosing SBS modified asphalt as the waterproofing system.

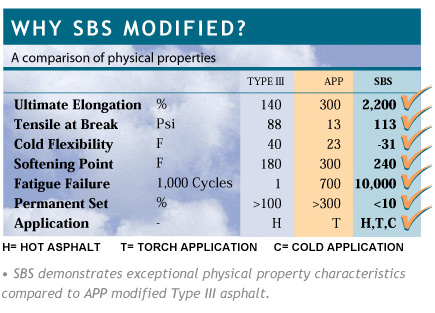

Despite asphalt’s unpraiseworthy performance in extreme weather (it becomes brittle in the cold and fluid in the heat) it remains the most common material used for waterproofing. SBS (styrene-butadiene-styrene) is an elastomeric compound that substantially improves the properties of asphalt, including improving low-temperature flexibility and aging resistance.

SBS rubber is flexible and returns to its original shape even after being twisted or distorted in anyway. When SBS is introduced into roofing asphalt, a more durable form of asphalt is produced that better suits the needs of modern buildings.

Other advantages of SBS modified asphalt include:

-

Flexibility in application and throughout the lifespan of the roof.

-

SBS can be maintained by the buildings in-house staff whereas single ply membranes must be maintained by an authorized contractor.

-

SBS systems are applied in two to three ply applications and range from 220 to 300 mils in thickness. Single ply membranes are applied in one layer and range from 20 to 80 mils in thickness.

-

Multiple layers ensure penetration resistance and reduces workmanship error.

-

SBS performs even after 10,000,000 cycles of fatigue tests, whereas blown bitumen and APP modified bitumen fail early on.

Kinds of application methods:

-

Heat welded, which is best for buildings like schools and hospitals where using hot asphalt would be improper.

-

Cold adhesive, which reduces odors during installation.

-

Hot asphalt, which is the most financially advantageous method, especially for new construction and large projects.

-

Self-adhesive, which is ideal for projects that cannot perform the prior three application methods.

SBS modified asphalt creates a predictable and reliable waterproofing system for every building. MBTechnology produces a variety of SBS membranes including but not limited to the energy efficient Metalflex SBS or Layfast SBS roofing underlayment. Whether you’re renovating, re-roofing or waterproofing, consider using SBS for enhanced results on every project.

Learn more about MBTechnology in their RoofersCoffeeShop® Directory.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In