Roof takeoffs part 2: Manual measurement methods

April 21, 2025 at 6:00 a.m.By Central States.

Grab your tape measure and calculator because it’s time to dive into the technical parts of roof estimating.

In a previous article, we covered how important the roof takeoff is to a successful project. To refresh your mind, roof takeoff is a term that refers to the process of estimating the materials and dimensions of a roof. This information then allows contractors to plan a project accurately. This means ordering the right amount of materials, managing the project costs effectively and ensuring they have the labor needed for a project.

Today, the experts here at Central States Manufacturing will dive into how you can go about manually collecting the dimensions needed for the roof takeoff. This is one of two methods (the other being digital measurements), so make sure to keep an eye out for the third article in this series that explores that option!

Traditional manual measurements

Manual measurement involves physically accessing the roof to measure its dimensions. While this method is accurate, it is time-consuming and can pose safety risks, particularly on steep or complex roofs. If manual measurements are necessary, follow these steps:

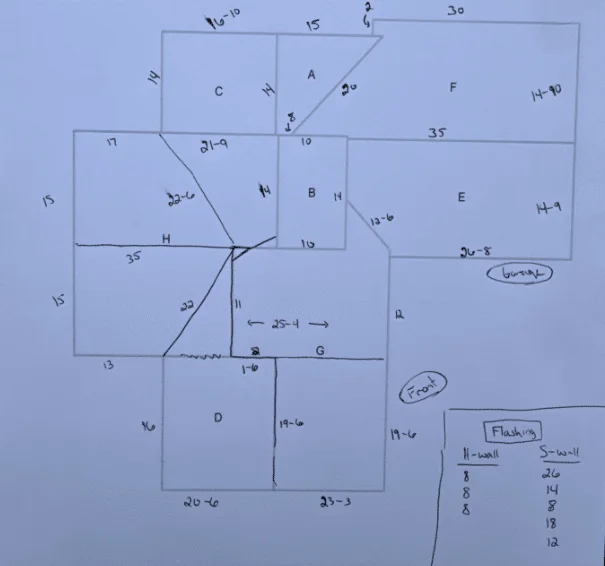

Draw it out

Starting from a sketch of the roof, complexities (like valleys, dormers, etc.), obstructions (chimney, vents, skylights, etc.) and which areas are being quoted. For example, the homeowner has requested a roof quote on the home but not the attached garage. You may want to take this opportunity to measure both roof structures in case the customer changes their mind or you can upsell them later for the garage. Be sure to include trees or wires that overhang the roof as they may make the installation more difficult or require additional labor for removal or proper attention (example: terrain of the yard around home, landscaping and so on).

Measure every roof section

Get on the roof and break out the tape measure! With your sketch in hand, break down the roof by section and measure the length and width of each section noting any irregular shapes and oddities, for example, the gutter line being a different length than the ridge or a squaring issue at a corner. This is a good time to note if all corners are square and which direction you will want to lay the metal panels (right to left or left to right), as determined by factors in the style and size of the roof sections as well as the panel chosen.

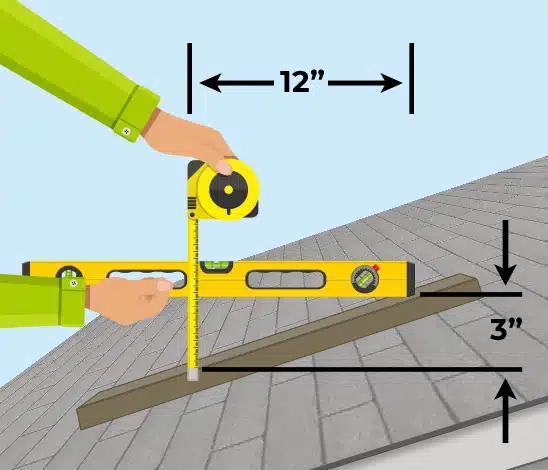

Account for roof pitch

Calculate the slope factor of every roof section and label the sketch accordingly. This factor is important in calculating the trim bend per roof section and in your own labor estimates, for example, higher slopes may need additional considerations for set-up of equipment and safety tools. Note that many roofs have multiple roof pitches, so be sure to measure each section of roof.

Roof pitch is the ratio of the rise (height) to the run (length) over a 12-inch span. For example, if a roof rises 6 inches for every 12 inches of horizontal distance, it has a 6:12 pitch. Once you know the pitch, you can use the chart below to find the angle of the roof for trim conditions as needed.

Calculate total area

Although metal roofing is not sold by “square,” but rather by linear foot, you may need to calculate total area if your customer is considering a variety of roof material options. Start by multiplying the length by the width of each section to find the area. Then add up the areas for all sections to determine the total square footage.

What’s next?

So far, you’ve collected information about the roof and the customers’ vision and ideas and now you’ve collected some hand-measurements of the roof. Before moving into the next step – calculating roof material needed, we will cover the digital method of measuring the roof next, a popular option with roofing contractors due to increasing accuracy of digital systems and the speed and ease of quoting.

Original article and photo source: Central States

Learn more about Central States Manufacturing Inc. in their Coffee Shop Directory or visit www.centralstatesco.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In