Carry your technical library in your pocket

By Julianne Calapa, Sheffield Metals International.

Meet the SMI Tech Stick, a powerful and user-friendly tool designed to help you bid and work on metal roof and wall projects.

If you’ve worked on any part of a metal project, you know that below the shiny surface of the panels is a mass of paper — there are many documents and files needed to keep a project moving behind the scenes. This can be everything from testing and engineering reports to warranty forms and product information. It’s important to keep these documents organized, as they are needed in a variety of scenarios and can be hard to find on the original websites in a pinch. This is why Sheffield Metals built the SMI Tech Stick!

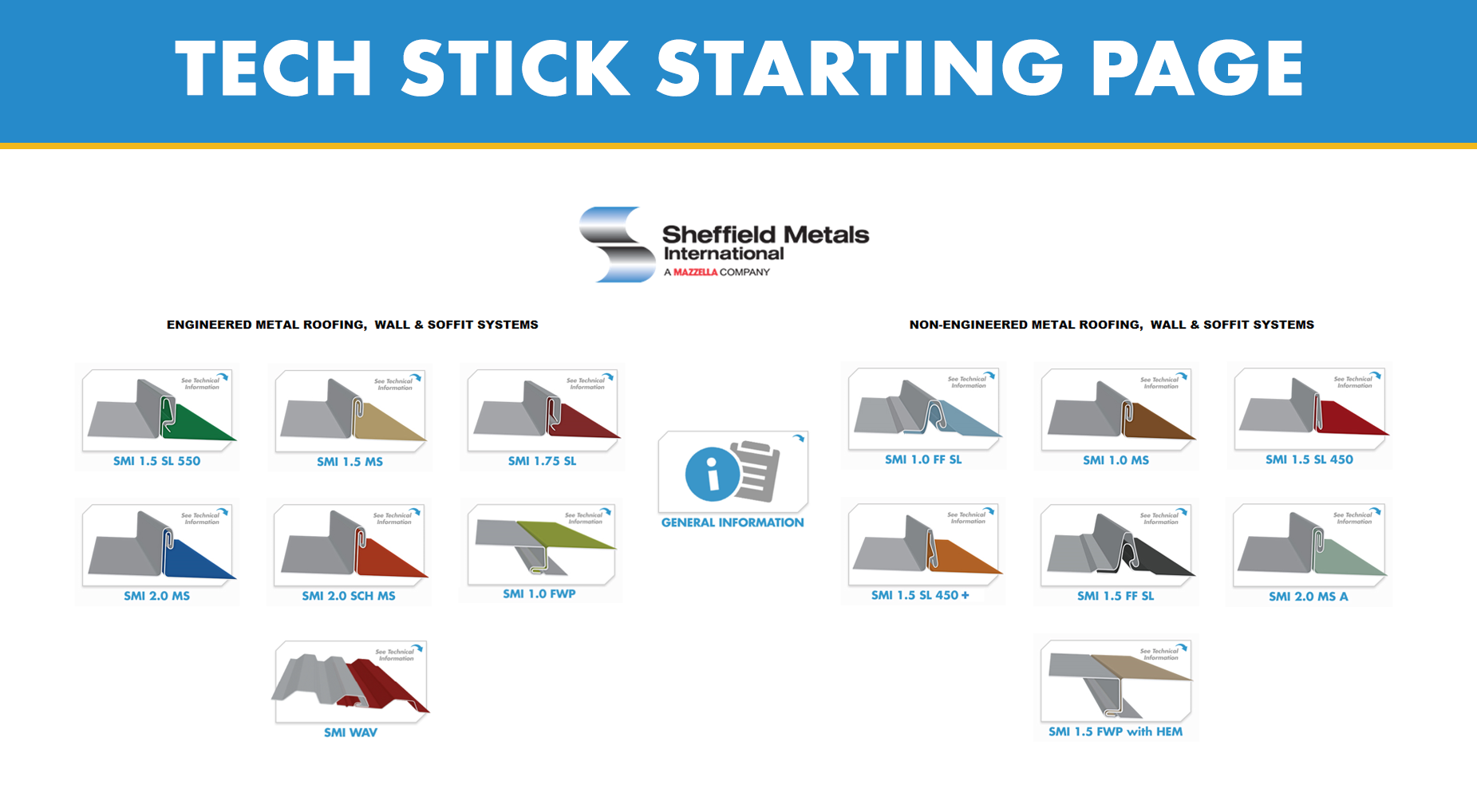

This tool is a flash drive the holds all the documents needed for a project submittal for an architectural specification. Plus, it’s a digital library of documents that won’t take up storage space. It was designed to be easy to navigate, especially when using the Tech Stick Starting Page interface, which makes it quicker and more efficient than asking for or requesting documents from an individual or team.

So, what are the details of the Tech Stick? What are some scenarios where the Tech Stick can help you with bid submittals, spec creation, etc.? Let’s discuss.

What is the SMI Tech Stick?

At its core, the SMI Tech Stick is a flash drive that contains Sheffield Metals’ entire library of technical resources, including:

- Demo video showing how to navigate the SMI Tech Stick

- Product submittal information

- Panel profile cutsheets

- Installation details

- Manufacturer’s specifications

- Engineering reports and testing documents (uplift, air infiltration, water submersion,

- Weathertight, paint and substrate warranty forms and documents

- Color cards and paint system information

- Calculators for coil, trim and more

- Accessory drawings and information (clip drawings, fastener information, etc.)

- Technical bulletins

- Rollforming machine brochures and documents

- LEED information

To understand the importance of the SMI Tech Stick, let’s go through some background on why Sheffield Metals created this tool.

The primary intention for developing the original Tech Stick was to have one easily accessible place that contained all of the documentation that a contractor needs to complete their submittals for architecturally specified projects.

In the past, contractors bidding on projects had to rely heavily on the profile supplier or manufacturer to get the required documents that an architectural spec called for. This led to a lot of back and forth that would be confusing, time-consuming and simply not conducive to sometimes tight submittal deadlines.

Our Technical Department took on this issue and set out to create a digital drive that was easy for users to access, navigate and transport between job sites, offices and travel. That’s how the SMI Tech Stick that exists today came into existence.

Who can use the SMI Tech Stick?

Over time, the SMI Tech Stick has transformed into a tool that benefits anyone in the metal roofing industry, including architects, contractors, regional manufacturers or panel suppliers and a few miscellaneous users. Let’s go into each of these audiences and how they can use the SMI Tech Stick to assist in their projects.

Contractors (mostly commercial and some residential)

As we mentioned, the most significant users of the SMI Tech Stick are commercial contractors who are composing project submittals and bidding on architectural specifications, as they often need to include a variety of documents for a submittal. While each submittal is unique, many require engineering reports, guide specifications, cutsheets and more to be included.

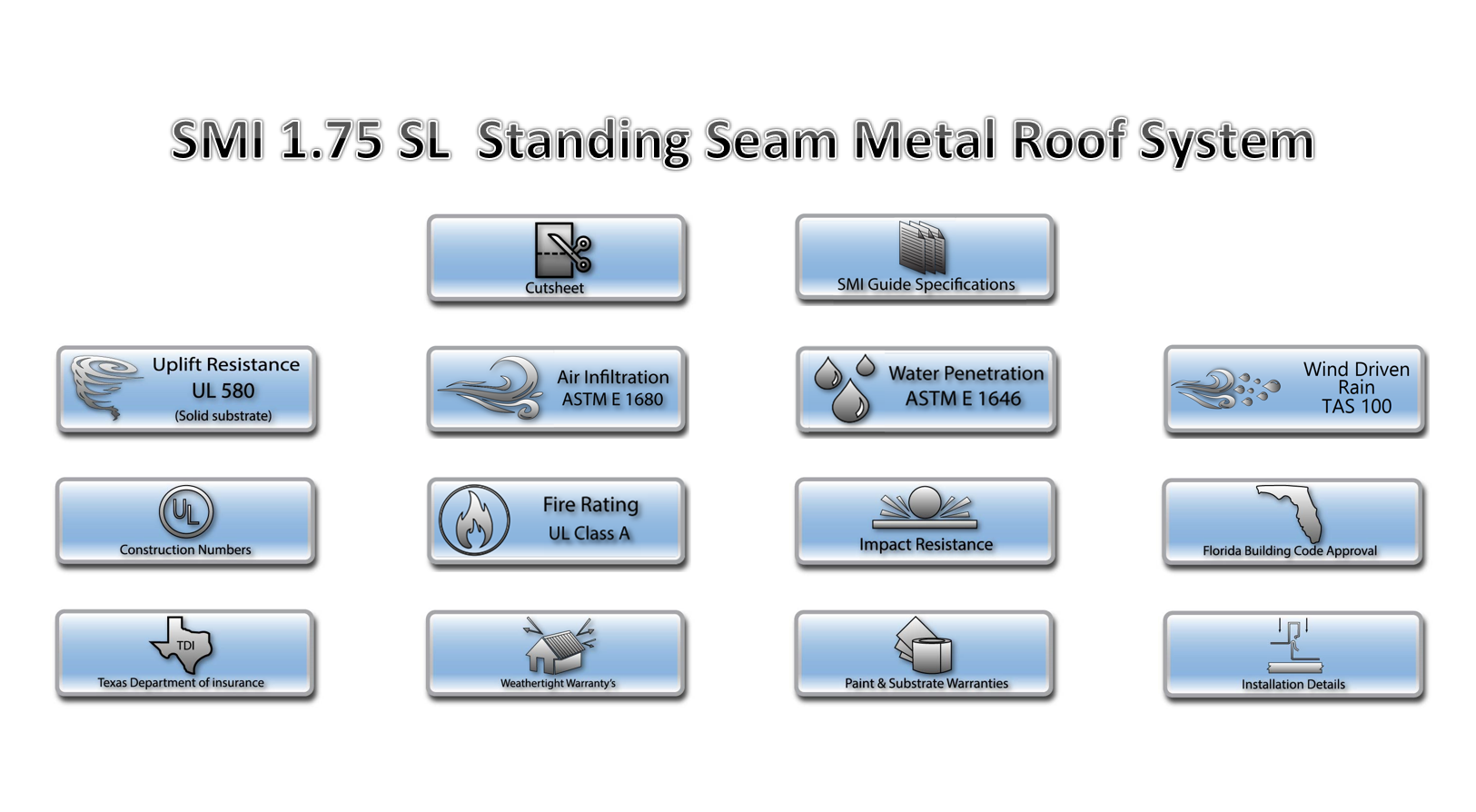

For a quick example, let’s say a contractor sees that the spec they’re bidding on is calling for an engineered standing seam metal roofing system that:

- Is a mechanically seamed panel profile

- Has a Galvalume (steel) substrate

- Can be installed over plywood

- Has a UL 580 & 1897 uplift test rating

All the contractor needs to do is go onto the Tech Stick Starting Page (see photo above) and then navigate through the mechanically seamed profile options to see if Sheffield Metals has a panel that meets these requirements. Since we do, the contractor can click on the profile and then select the correct metal substrate and roof deck material. Once those selections are made, a folder will open with all of the engineering documents available, so the contractor can easily select the ones they need and then attach them to their submittal.

Or, perhaps you’re a contractor who is at a consultation with a potential customer and they’re asking for a sample copy of a paint warranty document. Simply bring the flash drive with you, plug it into a USB port (USB accessing capabilities are also available for mobile devices) and go to the Paint & Substrate Warranties folder. There, where you can view the warranty documents and/or email them to the prospect.

Architects, spec writers and design professionals

In the past, many architectural firms had binders filled with technical information from individual manufacturers, which they referenced when building a specification. More and more firms are now switching to digital — and therefore more user-friendly — versions of these “binders,” which is essentially what the Tech Stick functions as.

Plus, we often hear that the SMI Tech Stick is utilized during the research stage of a design.

For example, let’s say an architect in Austin, Texas, knows they need to specify a panel profile with uplift resistance testing, air infiltration testing and a Texas Department of Insurance (TDI) approval. They can access the SMI Tech Stick to verify that profiles that have all of these elements even exist (they do!). Plus, they can directly use any of the information on the Tech Stick to name Sheffield Metals as the requested product manufacturer.

Regional manufacturers and panel suppliers

While a regional manufacturing business likely won’t use the SMI Tech Stick as much as a contractor or architect, it’s still a valuable tool that can help their business. Again, it puts all relevant information about a panel profile in one easy-to-reference place.

An example of when a regional panel manufacturer might use the Tech Stick is if they’re helping one of their contracting customers with a bid/submittal. Or, if they need to reference one of the panel profile cutsheets on the fly while running panels, all of that is possible using the SMI Tech Stick.

Additional miscellaneous users

We’ve come across other individuals in the industry who benefit from having a Tech Stick of their own, including:

- Building engineers and consultants (especially for access to engineering reports)

- General contractors

- Builders

- Wholesale or retailers

- Some select home and building owners

Recap of 5 reasons you should have an SMI Tech Stick

1 - It makes architectural metal roofing product submittals and bidding easier for the contractor and the architect. All you need to do is copy and paste any of the documents, PDFs or files that you need into your submittals, communications (emails), etc.

2 - It’s the size of a standard flash drive, so it’s easy to transport and carry around. You can seamlessly keep the drive in your backpack, in your work vehicle, in/on your desk, on your computer and beyond — all without it taking up too much space. Plus, everything on the flash drive is digital and won’t take up storage space on any of your devices.

3 - It will save you time. The Tech Stick can help to reduce the following:

- Time spent requesting and waiting for the documents you need to complete your submittal(s). Remember that we have dedicated Technical and Architectural Departments that will help with any questions or requests you have as soon as possible. Still, we understand that many project submittals have a short time window to complete.

- Time spent on the website searching for information or documents, which are often in different areas of the website.

4 - New versions come out as significant changes are made to any of the information on the Tech Stick. For example, Sheffield Metals recently came out with a new version (version 3) in the second half of 2022, as we added recent testing reports, updated cut sheets and guide/manuspecs, added FBC approvals and more. The newest flash drive is gray (it used to be blue).

5 - It’s 100% free. There is no fee to get an SMI Tech Stick sent to you. All you need to do is submit the form on the Tech Stick page and then a member of the Account Management team in your region will send you one.

Now that you’ve learned the full capabilities of the SMI Tech Stick, it might be just the tool your business needs to work more efficiently and achieve the next level of project success.

At Sheffield Metals, we want to make working with, specifying and bidding with our products as easy as possible, which is exactly why the SMI Tech Stick was developed. Plus, we value transparency in all that we do and that’s why everything you could need for a metal roofing project is on the Tech Stick.

Original article source: Sheffield Metals International

Learn more about Sheffield Metals International in their Coffee Shop DIrecotry or visit www.sheffieldmetals.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In