Building resilience in paradise

January 3, 2025 at 6:00 p.m.By Roof Hugger.

When the winds howl, these roofs hold their ground.

Nestled in the shimmering blues of the Caribbean, the Cayman Islands are the epitome of island charm — palm-fringed beaches, endless skies and crystalline waters. But beyond the idyllic postcard image lies an architectural battle against the elements. Amid the serene beauty of Grand Cayman, a fascinating story unfolds: a race to fortify rooftops against the fury of hurricane-force winds. What makes these metal roofs so extraordinary and why are industry leaders betting on cutting-edge solutions to weather the storm? Here at Roof Hugger, we share the answers which are as captivating as the island’s sunsets.

Precision Industries Cayman LTD, located in the city of Georgetown on Grand Cayman, was called in to do a metal roof retrofit for one of their customers. The main criteria of the job was to make sure the new metal roof could withstand the strong winds of most hurricanes. Being familiar with metal roof retrofits, Precision knew the go-to sources for this job would be Atas International for the coil to roll form the new roof panels on site and Roof Hugger LLC for the framing system to properly support that new roof.

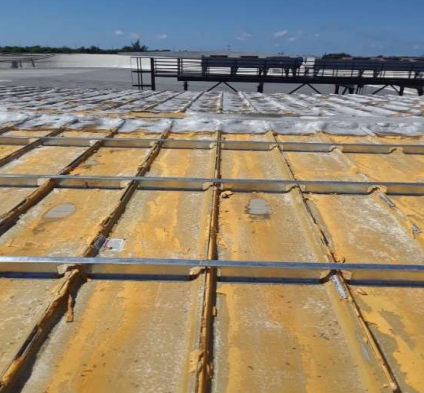

With the building having an original 24” trapezoidal standing seam roof on top, they would need to use the Roof Hugger 4.5” tall Model-D sub-purlins, which would be structurally attached to each existing purlin, through the existing panel. To ensure that the new .040 aluminum, 16” o.c. vertical rib 2” standing seam panel attached with ASMI stainless steel clips can fend off the strongest of winds, Precision Industries added the Roof Hugger hat over hat corner grid system which allows for tighter clip spacing in the most vulnerable zones of the roof. That system consists of hat sub-rafters installed from purlin to purlin, at 2 ft o.c. spacing and then the hat sub-purlins attached on top, running parallel with the eave to create clip attachments every 2’-6” in each corner of the building.

Finished Roof Ridge

Finished Roof

With all the right parts in place, this building in a tropical island paradise is now ready to face the next hurricane!

Original article source: Roof Hugger

Learn more about Roof Hugger in their Coffee Shop Directory or visit www.roofhugger.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In