A Guide to Architectural Shingles

By Trevor Underwood, DECRA.

Learn how to tell the difference between architectural shingles and 3-tab shingles and other interesting facts with this helpful guide from DECRA!

Have you ever had a customer that didn’t know the difference between architectural shingles and other types of shingles when it comes time to picking a material for their project? Or perhaps you haven’t branched out into the specifics of what sets architectural shingles apart from other products on the market. Here is everything homeowners and building owners need to know about this style of shingle and what they may need to know when planning their next project!

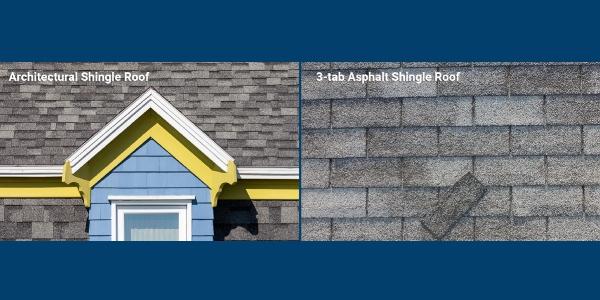

There are two major differences between architectural shingles and 3-tab asphalt shingles: quality and appearance.

Let’s start with quality.

Since 3-tab shingles are made from a single layer of asphalt, they are thin, flimsy and vulnerable to damage from the elements. They also have one of the shortest lifespans of any roofing material and need to be replaced as often as every 12 years.

Architectural shingles have multiple layers of asphalt that are bonded together, resulting in a thicker and more durable asphalt roofing product. They are also made with higher-quality asphalt, have stronger adhesives and last longer than 3-tab asphalt shingles

When it comes to quality, architectural shingles are a superior product when compared to 3-tab asphalt shingles.

When it comes to appearance, it’s fairly easy to tell the difference between an architectural shingle roof and a 3-tab asphalt shingle roof. All you need to do is look at the thickness and uniformity of the shingles.

Architectural shingles are thicker and have varied sizes and shapes to create a more interesting, appealing and dimensional roof. Three-tab asphalt shingles are uniform in both size and color.

What are the pros and cons of architectural shingles?

When architectural shingles were first introduced in the 1980s, they were quickly embraced by homeowners in search of a roofing material that was more durable and longer-lasting than 3-tab asphalt shingles.

While architectural shingles have many advantages over 3-tab asphalt shingles, they are essentially just an upgraded version of the cheapest roofing material on the market.

This is important to know because asphalt shingles of all grades, including architectural shingles, have shortcomings.

All asphalt roofs are prone to cracking, splitting, curling and warping around the edges after a few years of exposure to the elements. Homeowners in regions prone to hail, high winds, tornados or hurricanes may want to consider a stronger type of roof.

Additionally, asphalt roofs are extremely heavy, and since architectural shingles weigh up to 50% more than 3-tab asphalt shingles, they are one of the heaviest roofing materials on the market. Many homeowners are surprised to learn that heavier is not better when it comes to roofing since it can make the roof dangerously top-heavy and require additional construction to support the weight of the roof. Modern roofing materials, such as metal roofing, are lightweight and more durable than architectural shingles.

Another drawback of any asphalt roofing product is its impact on the environment. Asphalt roofs are one of the worst performers when it comes to energy efficiency since they absorb heat like a sponge and radiate the heat down into the home long after the sun has set.

Worse, the short lifespan and frequent need to replace asphalt roofs, including architectural shingles, results in 11 million tons of landfill waste each year. And as a petroleum-derived product that requires fiberglass, tar and other petroleum products during the manufacturing process, asphalt roofs are neither sustainable nor biodegradable. Even recycling an old asphalt roof can cause more damage to the environment, as stated by the Innovative Waste Consulting Services in their Report for the Construction Materials Recycling Association:

“Regulatory concerns over potential environmental impacts, particularly with regard to asbestos, have to some extent limited the widespread recycling of discarded post-consumer asphalt shingles.”

While architectural shingles were considered innovative in the 1980s, they struggle to compete with the performance and style of modern roofing materials, such as metal roofing.

Architectural shingles versus metal roofing

Modern metal roofing products, like stone-coated steel, give homeowners the industrial-strength performance of steel in a wide variety of styles, textures, and colors to enhance the aesthetic requirements and curb appeal of any home.

While architectural shingles are superior to 3-tab asphalt shingles, they can’t compete with the longevity, durability and ROI of metal roofing:

- Metal roofs last two to three times longer than traditional roofing materials, such as architectural shingles.

- Metal roofs are engineered for high-performance protection and can withstand nearly anything Mother Nature has to offer, including hail, fire, hurricanes, tornados, high winds and earthquakes.

- Metal roofs are one of the most energy-efficient roofing materials on the market and can reduce cooling costs by up to 25%.

- A modern metal roof can increase home value by up to 6%.

Even insurance companies are aware of the durability of metal roofing and offer substantial discounts to homeowners with a metal roof.

In fact, Progressive calls out loud and clear on their website that “Your homeowner's insurance may cost less if you have a newer roof made of more durable materials, like metal or slate.”

While a metal roof is one of the most durable and long-lasting roofs on the market, some homeowners may worry that metal roofing will look too industrial for their home.

Metal roofing is a broad term for a wide variety of roofing products that are composed of some type of metal, including aluminum, standing seam, copper and stone-coated steel.

Stone-coated metal roofing bridges the gap between industrial durability and design versatility.

The manufacturing process begins with high-grade steel sheets that are “stamped” into a wide variety of shapes. Natural stone granules are added to achieve the same distinct textures and vivid colors of traditional roofing materials, such as asphalt shingles, clay tiles and wood shake.

DECRA Shingle XD provides the depth and dimensional look of architectural shingles with the high-performance strength of stone-coated steel.

Can you tell the difference? Which of the four homes below has a stone-coated metal roof?

Hint: Two homes have a stone-coated metal roof and two homes have an architectural shingle roof.

Ready for the answers?

The first and the third homes have DECRA Shingle XD. The second and fourth homes have architectural shingles.

Experience the DECRA difference

DECRA Metal Roofing’s line of stone-coated steel roofing products give homeowners industrial-strength performance without industrial-strength style.

As the original stone-coated metal roofing manufacturer, DECRA Metal Roofing products have withstood the test of time since 1957. Manufactured at our state-of-the-art facility in Corona, California, DECRA roofs are constantly tested above and beyond the requirements to ensure the quality that DECRA is known for is present in each and every stone-coated metal roofing panel we produce.

Ready to see and feel the DECRA difference? Click here to order a free sample.

Original article source: DECRA

Learn more about DECRA Metal Roofing in their Coffee Shop Directory or visit www.DECRA.com.

Recommended For You

Six Factors to Consider When Selecting a Roof Restoration System

Read More ...

Growing With the Roofing Industry for a Better Tomorrow

Read More ...

Do Mobile Homes Have to Comply With Building Codes?

Read More ...

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In